technological innovation

What is the density of aluminum composite panel material? GDAA will provide the answer for you.

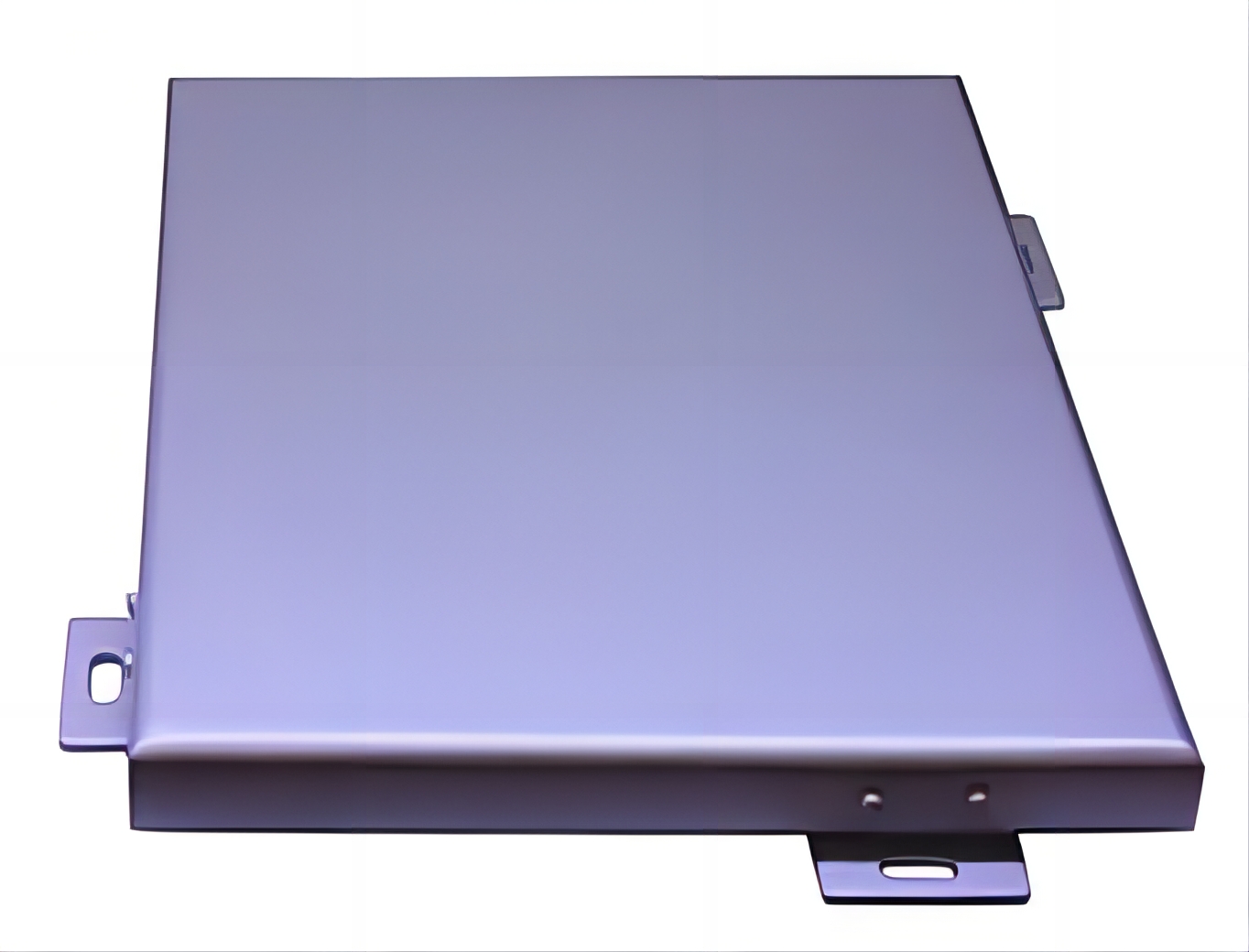

As a rising star in the metal curtain wall material industry, aluminum composite panel (ACP) has gained attention from project owners, construction companies, and target customers. Its popularity is growing, and it is expected to become even more popular. Meanwhile, the production and manufacturing process management of ACP manufacturers is a comprehensive system that requires strict adherence. Many processes may seem simple, but they are actually quite complex in practice. So, what is the density range of aluminum composite panels? Today, let's explore this topic together with GDAA, and hopefully, it will be helpful to you.

1.Density of Aluminum Composite Panels

As we all know, the density of aluminum varies with its purity. The higher the impurity content or the lower the aluminum content in aluminum alloy panels, the higher the density. The density of aluminum composite panels is approximately 2670 kg/m³. Current density refers to the current flowing through a conductor per unit area, and the typical current density for aluminum is around 6A/mm².

Aluminum composite panels are lightweight and high-strength metal decorative materials. For example, for a 3.0mm thick aluminum composite panel, the weight per square meter is about 8kg, and the tensile strength is approximately 100-280N/mm².

Aluminum composite panel products have excellent durability and corrosion resistance. Due to the use of advanced fluorocarbon spraying technology at home and abroad, they can effectively protect the wall. The service life can reach more than 15 years, or even around 25 years, making them highly durable. Aluminum composite panels have good processability. They undergo sheet metal processing first, followed by fluorocarbon spraying, allowing them to be processed into various geometric shapes such as curves, spheres, and flat surfaces.

2.Key Advantages of Aluminum Composite Panels

Uniform Coating and Rich Color: Aluminum composite panels have a uniform coating, and their surface offers a wide range of colors. Advanced electrostatic technology is used in the production process to ensure the even spraying of paint on the aluminum surface. The color can be chosen according to different customer requirements, meeting various design needs.

Stain Resistance and Easy Maintenance: Aluminum composite panels are not easily stained and are easy to clean. The non-stick nature of the coating prevents pollutants from adhering to the surface, keeping it clean. The fluorocarbon coating on the surface of the aluminum composite panel is non-adhesive, making it difficult for stains to adhere, thus reducing maintenance and cleaning efforts.

Easy and Efficient Installation: Aluminum composite panels are easy and quick to install. They are processed and shaped by the manufacturer, and when transported to the construction site, they do not require any cutting and can be directly fixed to the frame.

100% Recyclable: Aluminum composite panels are fully recyclable. Unlike other decorative materials such as glass, stone, ceramics, and aluminum-plastic panels, they have high recycling value.

It can be seen that aluminum composite panels are very convenient to use and offer excellent decorative effects. However, before purchasing, it is important to consider the actual usage requirements to ensure proper application.

RELATED NEWS

- Not sure about the T4, T5, and T6 materials of aluminum profiles? This article h 2024-03-20

- How to use aluminum profile section design skills to solve extrusion production 2024-03-19

- Factors affecting the life of trimming and punching molds 2024-03-12

- Overview of Steel/Aluminum Welding Technology 2024-02-29

- Steel belt conveying direction 2023-09-26

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China