News

O+ Tower Project Showcases Our Production Prowess

Omega Tower: Zaha Hadid Architects has dedicated its efforts to create a new chapter in the curtain wall project

Shenzhen, China - OPPO's global headquarters, the Omega Tower, designed by Zaha Hadid Architects, has now entered the curtain wall production phase.

With its unique concept of vertical urbanism and stunning design, this landmark building is about to add a splash of color to the Shenzhen Bay skyline.

A model of vertical urbanism

The Omega Tower is made up of four interconnected towers of different heights, breaking the stereotype of the traditional tower building. Its multi-curved,

special-shaped structure design, no standard layer and standard parts, showing a very futuristic architectural form. The overall structure adopts the form of

"steel frame + reinforced concrete core tube", and the total amount of steel structure is about 25,000 tons, showing extraordinary engineering strength.

Innovative design, reshaping architectural aesthetics

In a bold innovation, the core tube is pulled away from the main building, and the tower gradually shrinks and rotates from top to bottom, forming a unique

curved structure that creates the visual impression of the building floating in the air. The "olive" architectural style not only releases the interface along the street,

forming an open municipal space, but also gives a panoramic view of the magnificent landscape of Shenzhen Bay, achieving a harmonious coexistence between

architecture and nature.

Curtain wall Engineering: Challenges and breakthroughs

The Omega Tower curtain wall project is a world-class challenge, one of the most complex hyperboloid glass curtain wall projects in the world. The project covers

three types of curtain wall systems (hyperboloid unit curtain wall, hyperboloid exquisite steel frame curtain wall, frame curtain wall) and a variety of glass bending

forms (flat cold formed glass, cylindrical cold formed glass, hyperbolic hot formed glass, etc.), which integrates a variety of complex processes in one.

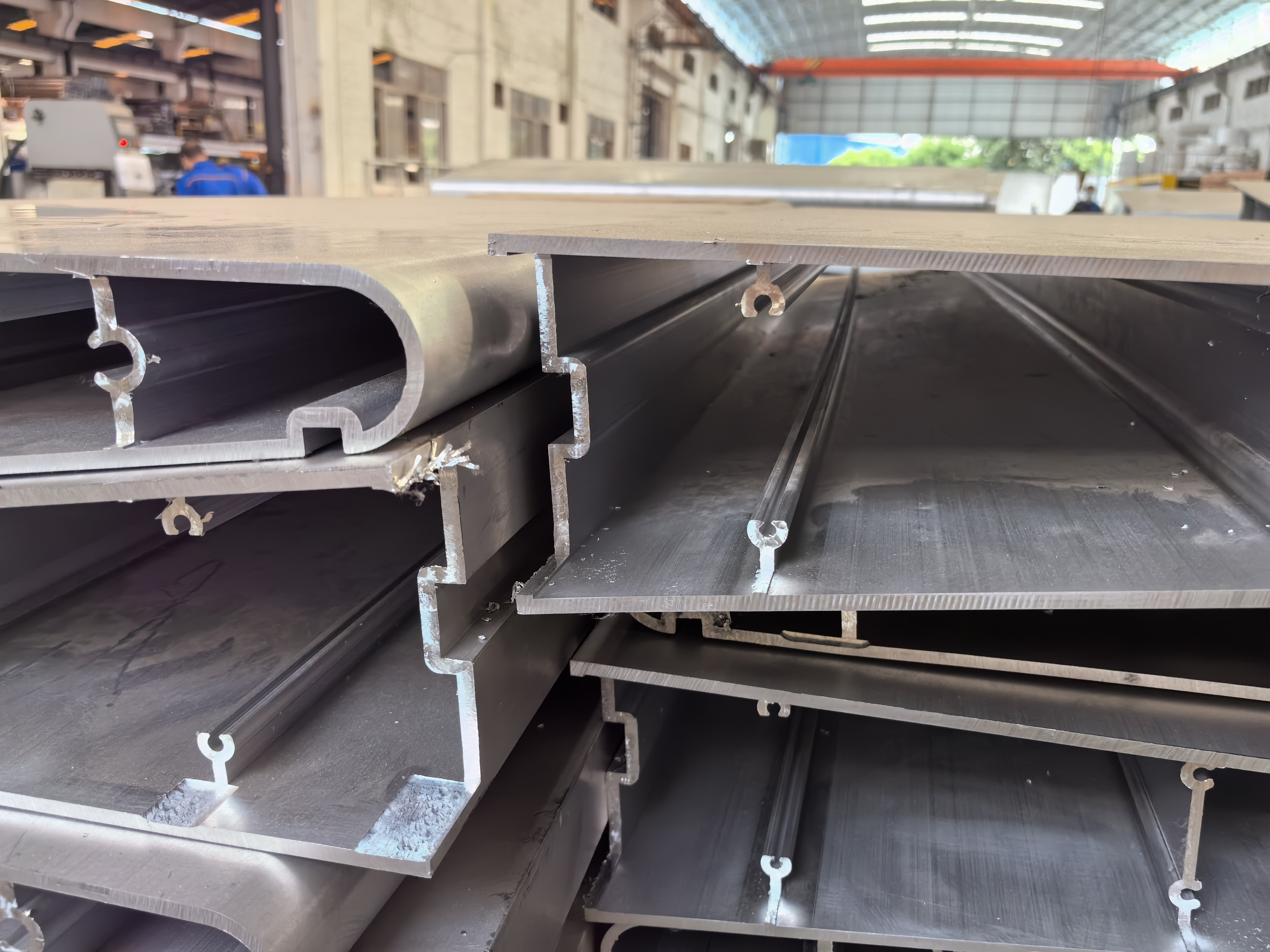

Exquisite workmanship, casting extraordinary quality

The curtain wall project has very high requirements for the stretching and bending processing technology of aluminum profiles. It is necessary to stretch and bend

the aluminum profiles first, then cut them, and assemble the connecting parts of the profiles after drilling and milling. These production processes are difficult to

achieve for general stretch-bending profile factories. However, with our advanced technology and rich experience, we can complete extrusion production, stretch

bending, cutting, drilling and milling, laser engraving and assembly of profiles in one go to ensure the perfect presentation of the curtain wall project.

The Omega Building, about to be crowned

The Omega Building is not only a building, it is a work of art, it embodies the essence of Zaha Hadid Architects design, but also shows the peak level of curtain wall

engineering technology. Let us look forward to the early completion of this landmark building, adding a bright light to Shenzhen!

RELATED NEWS

- Guangdong Aluminum Association and Moscow University Business School visited Gua 2024-12-12

- Guangdong Aluminium Association International Trade Co., Ltd. signed an overseas 2024-11-21

- Guangdong Aluminum Association International Trade Co., Ltd. Participates in the 2024-11-15

- Simplified Approach to Spandrel Area Treatment in Curtain Wall Glazing 2024-10-25

- ‘Aluminium alloy bending process: shaping elegant curves and enhancing material 2024-10-22

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China