technological innovation

Steel belt conveying direction

The following, in combination with practical issues in the stamping production process and an analysis case of online strength detection equipment for steel mills, explains the causes of the "orange peel" phenomenon.

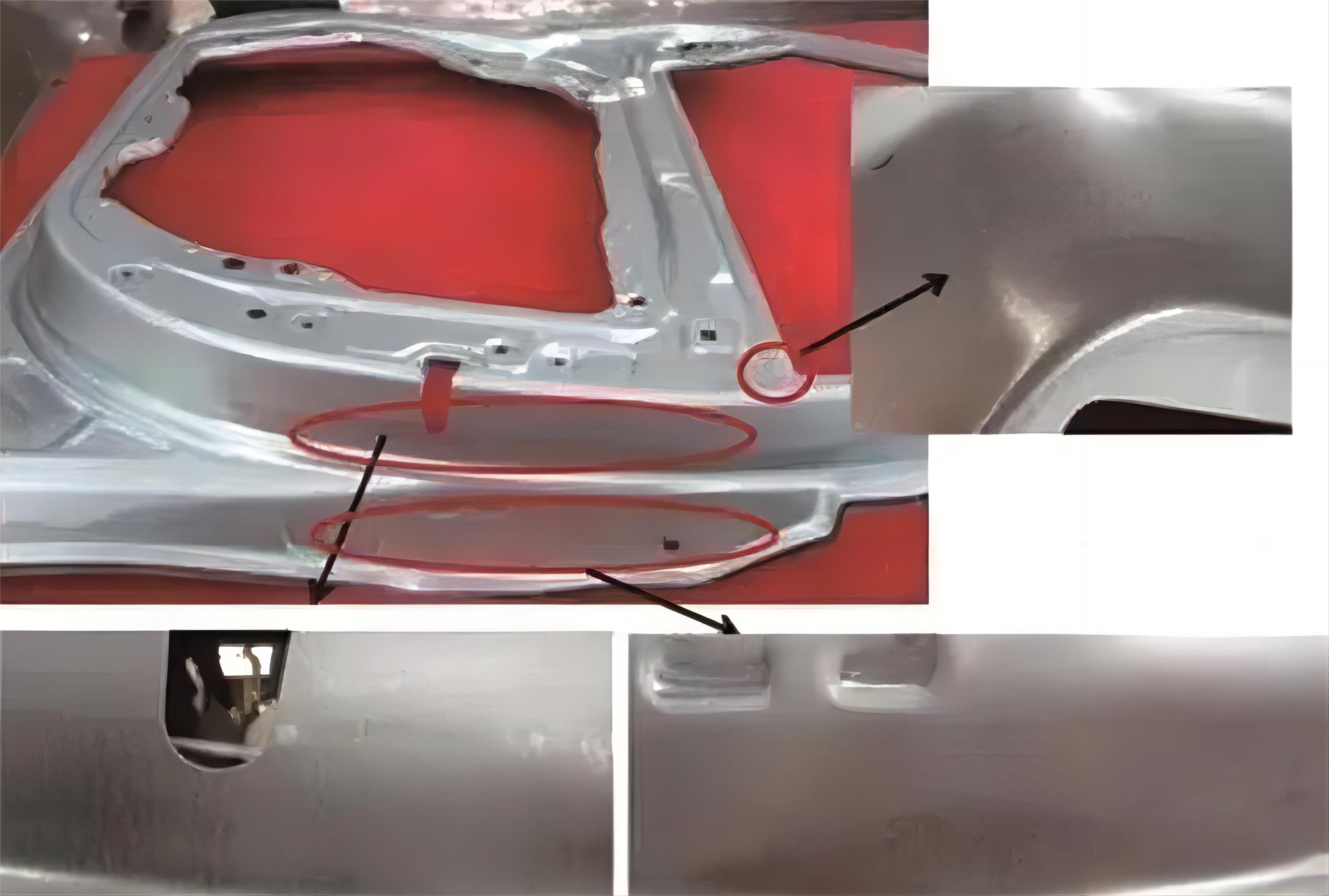

Punching reveals orange peel

In the stamping workshop, during the production of the V213 door inner panel component using steel coil number 426128_1, a "orange peel" defect has been observed on the surface of the stamped part, as shown in Figure 1.

Figure 1: Orange Peel Defect on the Inner Door Panel

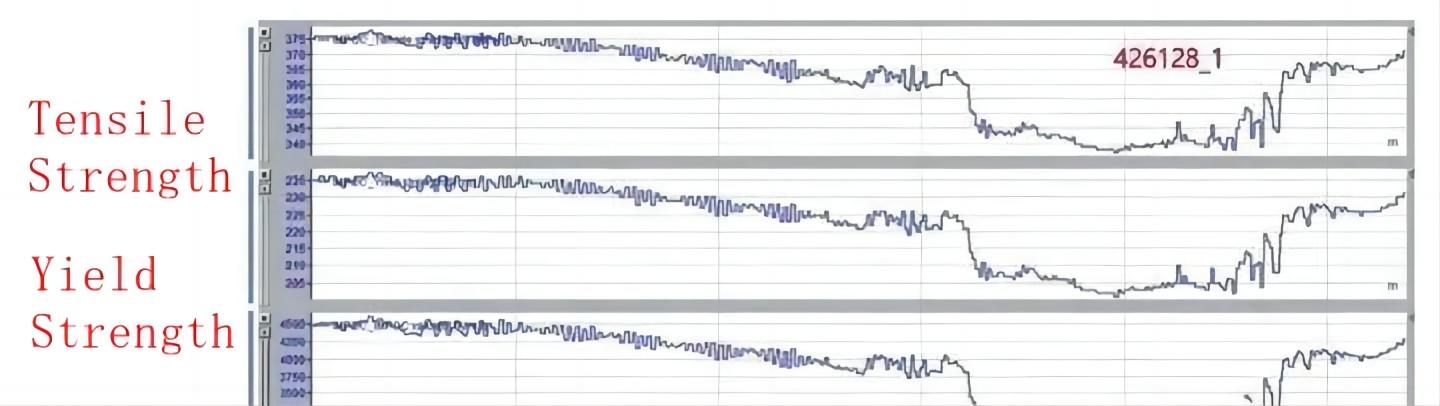

Steel Mill IMPOC Curve Investigation

During the traceability process, an abnormal IMPOC curve was discovered for coil number 426128_1, with corresponding yield strength and tensile strength both exhibiting abnormalities. Real-time test data approached the lower limit, as shown in Figure 2.

Figure 2 IMPOC curve and intensity anomaly

Investigation into the Abnormal IMPOC Curve

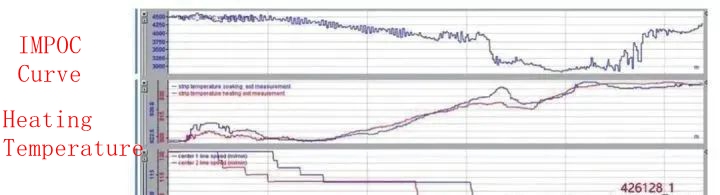

The retrieval of production process parameter data from the SAP system (Figure 3) revealed that there were two reductions in speed in the first section of the central part. This led to an increase in the temperature at the exit of the annealing and homogenization sections of the strip steel. As a result, the IMPOC-value decreased, posing a risk of non-compliance with mechanical performance at certain locations on the coil.

Figure 3 Process parameter curve

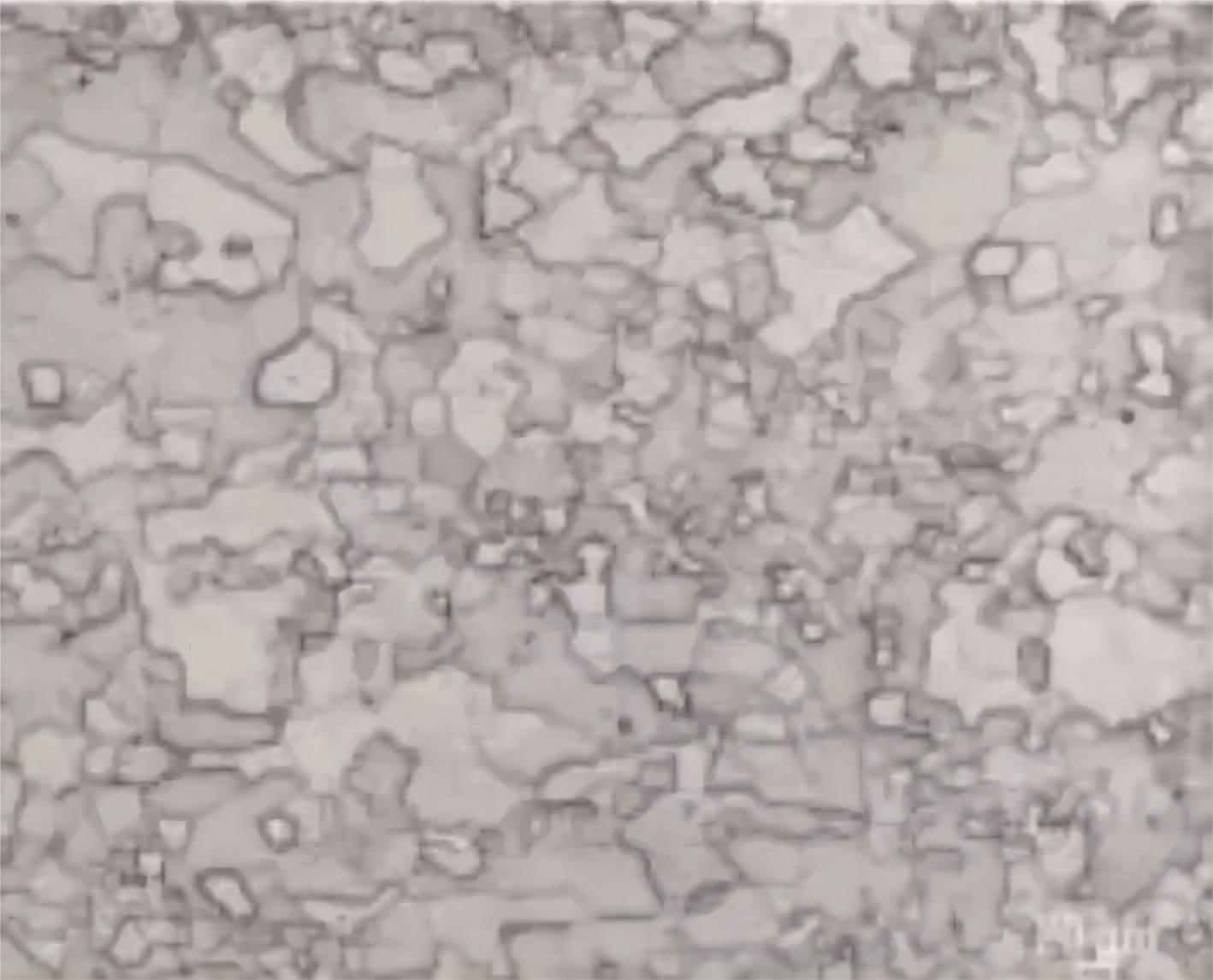

Material Reinspection Performance and Microscopic Metallography

Sampling analysis was conducted at the orange peel location on-site. Reinspection of the mechanical properties showed that the yield strength was lower, approaching the lower limit of the standard requirements. Upon reinspection of the punch bowl, surface cracking was observed, and orange peel appeared in areas with significant deformation, as shown in Figure 7. Microscopic grain structure analysis after stamping revealed uneven grain size distribution, with grain size levels ranging from 6 to 8, as shown in Figure 4.

Figure 4 Microscopic grain size

Conclusion

The occurrence of orange peel defects in the stamping process was attributed to the uneven grain structure of the material caused during the steel mill annealing process. The material strength online testing equipment can detect fluctuations in tensile strength, yield strength, and mixed crystal defects resulting from uneven grain size.

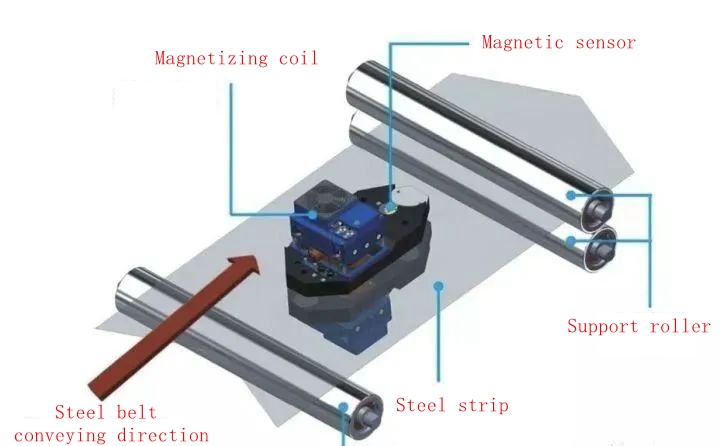

Such defects can be eliminated through the use of a material strength online testing system for stamping materials. The principle involves employing an electromagnetic induction automatic measurement system (IMPOC system, as shown in Figure 5) for automatic non-destructive online testing of the mechanical properties (tensile strength and yield strength) of ferromagnetic strip materials. The system simplifies the evaluation of the quality of stamping materials, allowing for continuous assessment of mechanical properties along the length and width of the entire strip. If one or more mechanical performance parameters exceed the specifications, the corresponding areas of the strip are alerted, and optional additional tests are performed. This ensures that the strength of each stamped part meets the standards, prevents batch quality issues, and ultimately meets the safety requirements for stamped parts in the entire vehicle.

RELATED NEWS

- Not sure about the T4, T5, and T6 materials of aluminum profiles? This article h 2024-03-20

- How to use aluminum profile section design skills to solve extrusion production 2024-03-19

- Factors affecting the life of trimming and punching molds 2024-03-12

- Overview of Steel/Aluminum Welding Technology 2024-02-29

- The techniques you must know for aluminum processing 2023-09-12

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China