technological innovation

Although burrs are small, they can be harmful! How to solve the burr problem?

Burring is a common issue encountered in metal processing, such as drilling, turning, milling, and sheet metal cutting.

One of the hazards of burrs is that they are prone to cause cuts and injuries. To remove burrs, a secondary operation called deburring is usually required. Deburring and edge finishing for precision components may account for 30% of the finished part's cost. Additionally, secondary finishing operations are difficult to automate, making burrs a challenging issue to address.

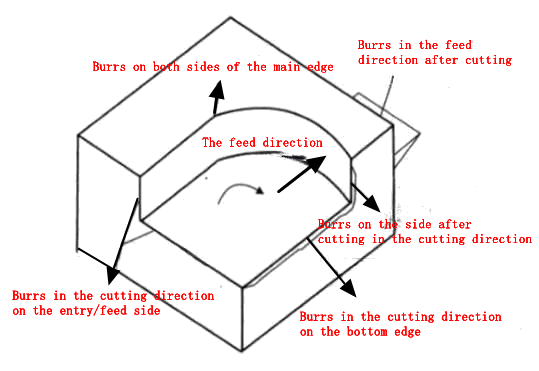

All the headache-inducing areas prone to burrs are listed here

In the machining process, there are burrs in the feed direction (entrance and exit burrs), as well as lateral and cutting direction burrs.

How to solve burrs

1.Chemical deburring

Chemical deburring is a processing method that utilizes chemical energy. Chemical ions attach to the surface of the workpiece, forming a protective film with high resistance and low conductivity to protect the workpiece from corrosion. The burrs, being raised above the surface, can be removed through chemical action. This deburring method is widely applied in fields such as pneumatics, hydraulics, and engineering machinery.

2.High-temperature deburring

This process is called "Thermal Deburring." It involves placing the parts that need deburring inside a tightly sealed chamber. Then, the entire assembly is introduced into a mixture of hydrogen and oxygen under certain pressure. By igniting the mixture, it causes an explosion, releasing heat that burns off the burrs on the parts without damaging them.

3.Rolling Deburring

The parts and abrasives are placed together in a closed drum. During the rotation of the drum, the dynamic torque sensor, parts, and abrasives work together to grind and remove burrs. Abrasives can include materials like silica sand, wood chips, alumina, ceramics, metal rings, etc.

4.Hand deburring

This method is more traditional and also the most time-consuming and labor-intensive. It mainly involves manually using tools such as steel files, sandpaper, and grinding heads for polishing. The most commonly used tool in production nowadays is the deburring knife.

5.Process deburring

Edge rounding can refer to any action that removes the edges of metal components. However, it is typically associated with creating a radius on the edges of the part

Edge rounding

Edge rounding" is not simply removing sharpness or burrs, but breaking the edges of metal components to improve their surface coverage coating and protect them from corrosion.

The edge rounding machine includes

Rotary deburring: Suitable for edge deburring of laser-cut, stamped, or machined parts.

Manual grinding machine: Suitable for metal processing projects that require grinding, edge rounding, or deburring.

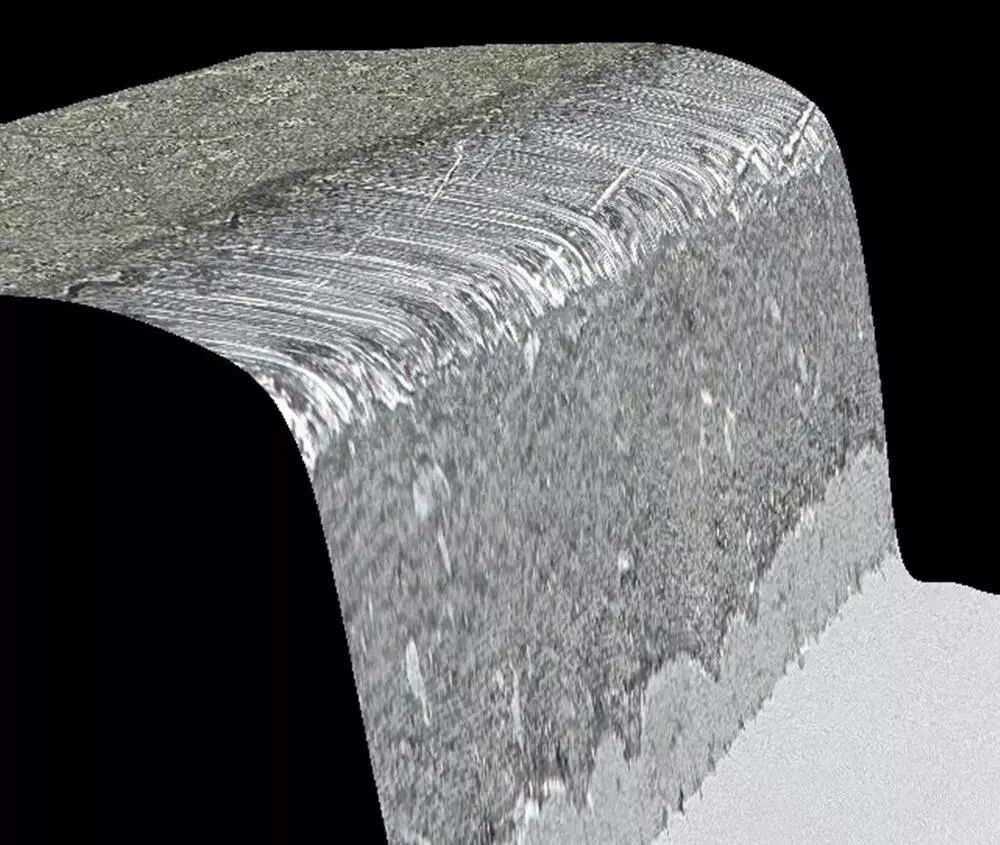

Special Challenge: Burrs in Milling Parts

In machining parts, burr removal is more complex and costly because milling at different sizes and positions can create multiple burrs. Therefore, selecting the right process parameters to minimize the size of burrs becomes particularly important.

The main factors affecting the formation of burrs during end milling are as follows:

1.Milling parameters such as milling temperature, cutting environment, etc., can have a certain influence on the formation of burrs. Some key factors, such as feed rate and milling depth, are reflected through the plane cut-out angle theory and the theory of Edge of Surface (EOS) exit sequence.

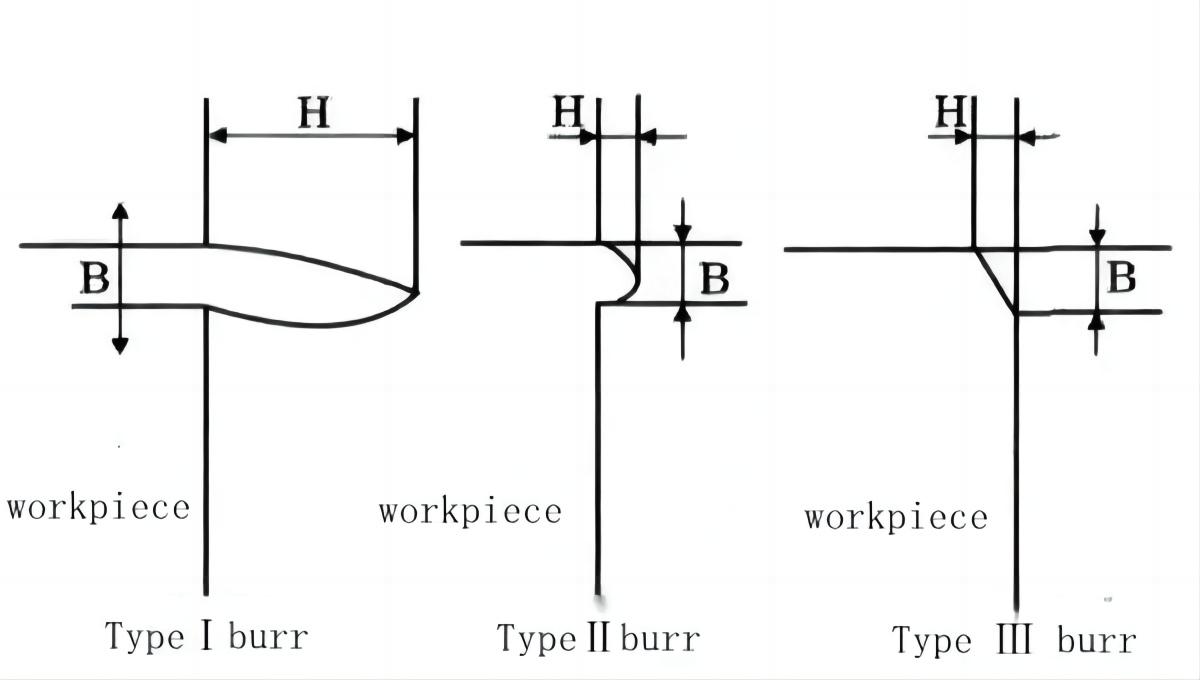

2. The plasticity of the workpiece material plays a significant role, with more ductile materials being prone to the formation of Type I burrs. In the end milling process of brittle materials, larger feed rates or plane cut-out angles can favor the formation of Type III burrs (depletion).

3.When the angle between the end face of the workpiece and the machined plane is greater than a right angle, the increased end face support stiffness can suppress the formation of burrs.

4.The use of milling coolant is beneficial for prolonging tool life, reducing tool wear, lubricating the milling process, and thereby reducing burr size.

5.Tool wear has a significant impact on the formation of burrs. When the tool is worn to a certain extent, the tool tip radius increases, leading to larger burrs not only in the tool exit direction but also in the tool entry direction.

6. Other factors such as tool material also have some influence on the formation of burrs. Under the same cutting conditions, diamond tools are more effective in suppressing burr formation compared to other tools.

How to effectively deal with the burrs generated during tool retraction

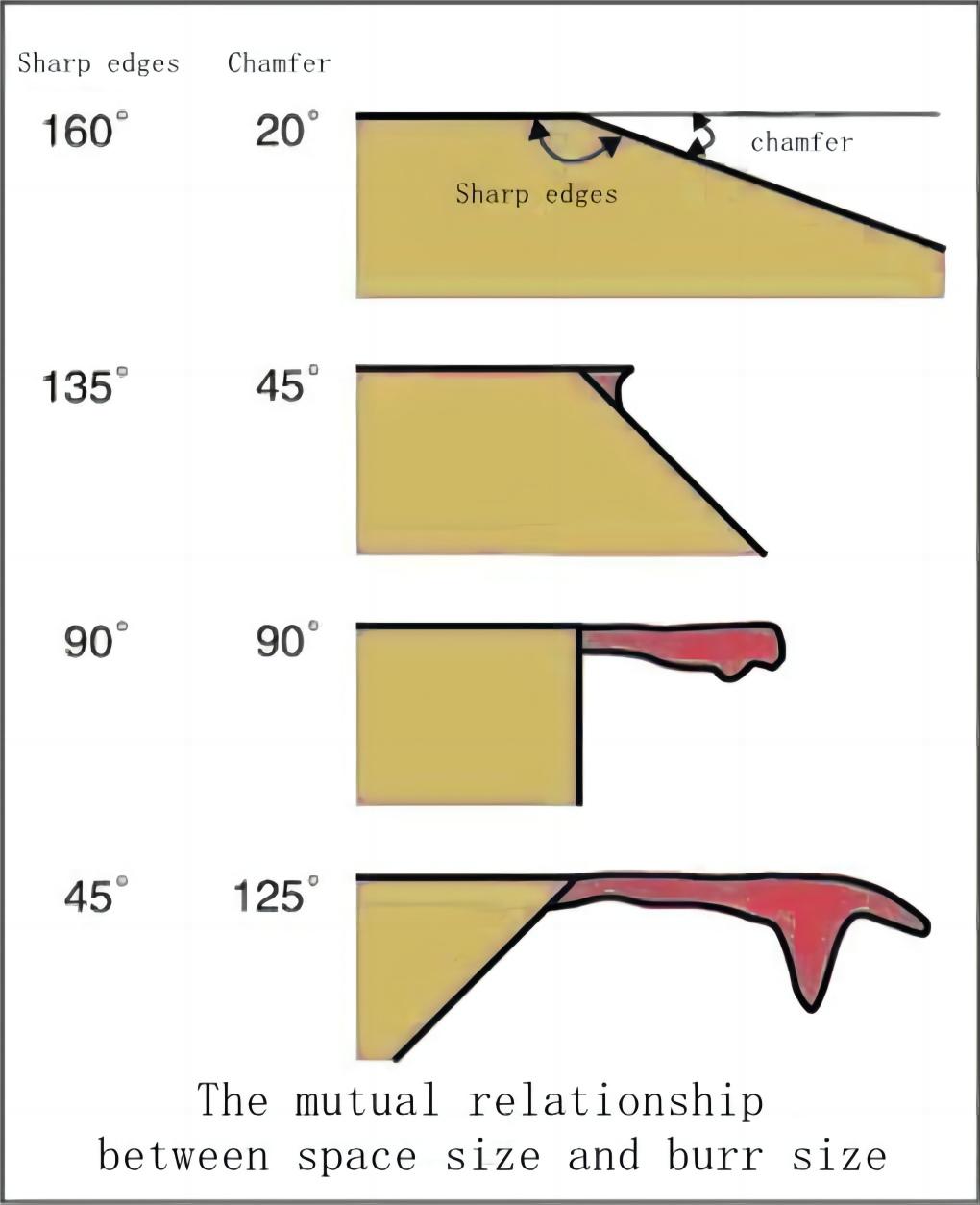

Minimize the space for burrs formation:

To suppress the burrs generated during tool retraction, it is effective to eliminate the space where burrs can form. For example, chamfering before tool retraction can be applied to reduce the available space for burrs.

Use appropriate cutting conditions to suppress burrs:

Minimizing cutting residues requires selecting the most suitable tools and cutting conditions. Choose tools with large front angles and sharp cutting edges. Increase cutting speed to improve cutting performance. Especially during precision machining, use the smallest cutting depth and feed rate possible.

The size of the tool and the space between the tool and the workpiece determine the size of burrs. Let's take a look at the relationship diagram below.

In fact, burrs are unavoidable in the machining process, so it is best to address the burr issue through process improvements and minimize excessive manual intervention. Using a chamfer end mill can reduce the space where burrs are generated and effectively remove burrs, making it a suitable method for burr removal.

RELATED NEWS

- Not sure about the T4, T5, and T6 materials of aluminum profiles? This article h 2024-03-20

- How to use aluminum profile section design skills to solve extrusion production 2024-03-19

- Factors affecting the life of trimming and punching molds 2024-03-12

- Overview of Steel/Aluminum Welding Technology 2024-02-29

- Steel belt conveying direction 2023-09-26

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China