technological innovation

How to prevent aluminum veneer bulging in summer

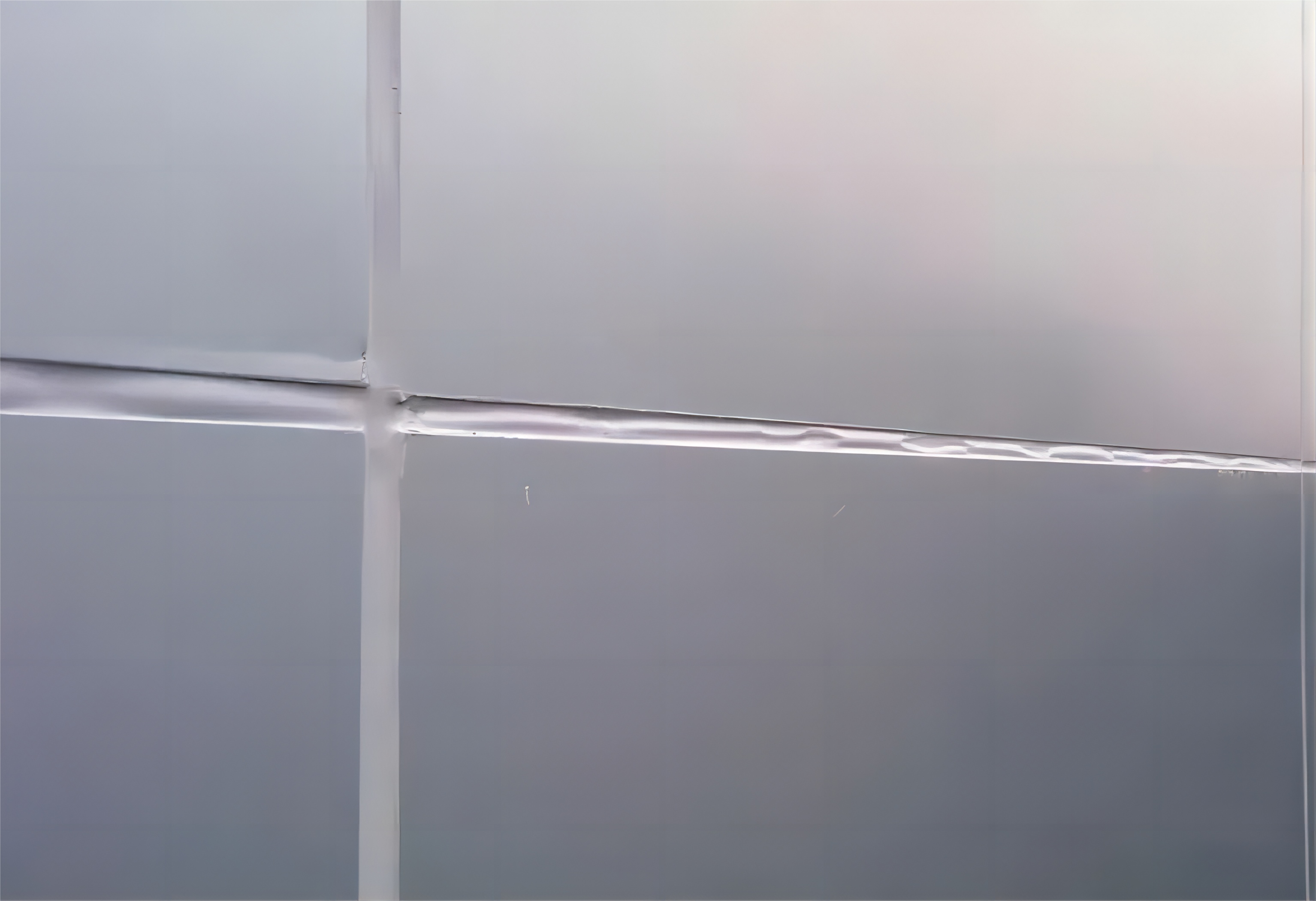

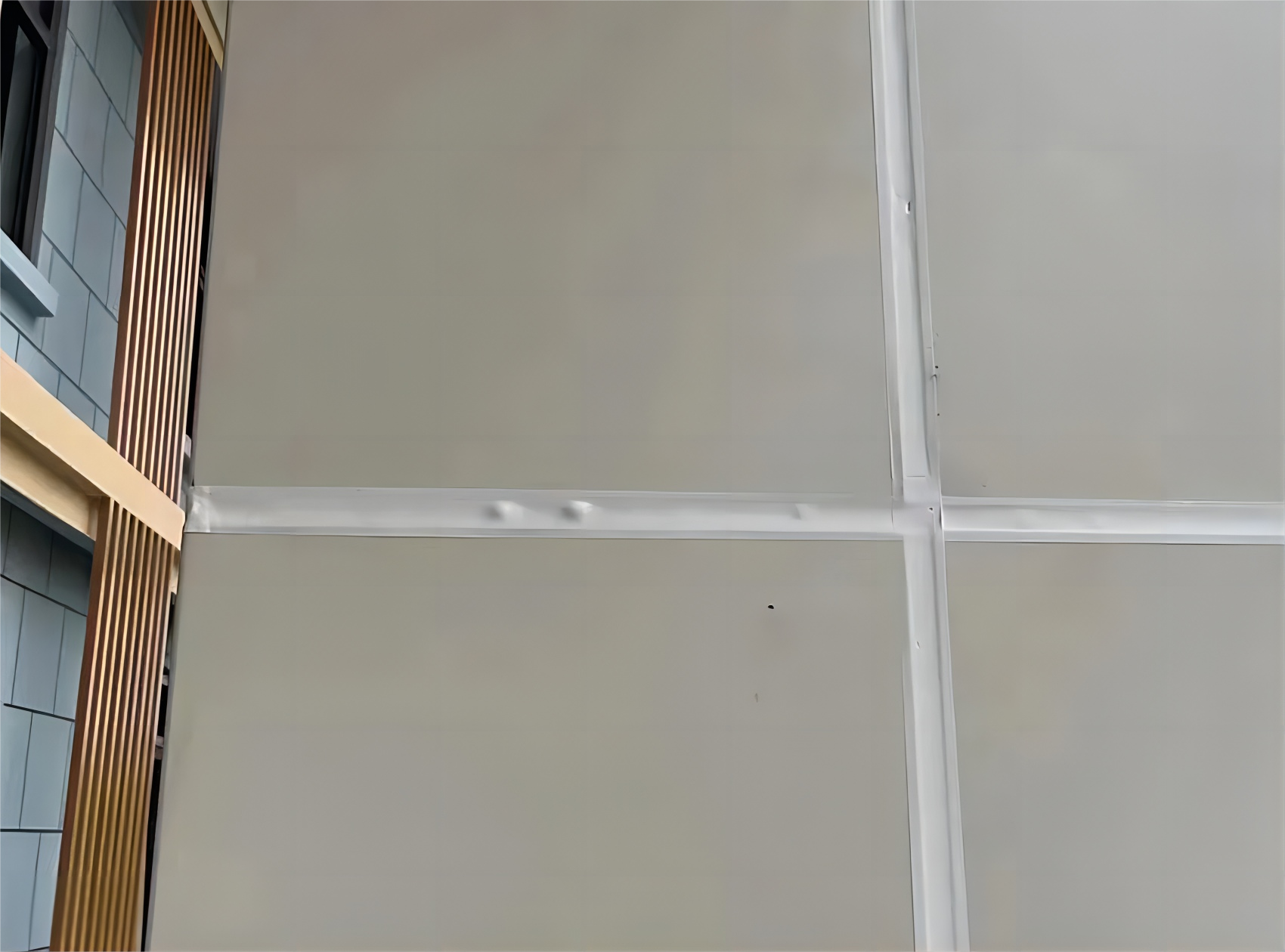

Summer is a common time for aluminum veneer bulging. Due to the higher temperatures during the summer, aluminum veneer tends to expand significantly when heated, which can lead to bulging at the connections between panels. Additionally, the high temperatures and humidity in summer can cause the surface of the aluminum veneer to expand further, exacerbating the issue of bulging

Causes of bulging

Environmental impact

In the summer, the high temperature causes the aluminum veneer to have a large thermal expansion coefficient. Direct sunlight on the surface of the aluminum veneer leads to heating and expansion of the aluminum sheet. When exposed to high temperatures, the aluminum sheet undergoes thermal expansion and contraction, resulting in deformation and warping of the aluminum veneer.

During the summer, strong winds may exert impact on the aluminum veneer if it is not firmly fixed or installed improperly, leading to warping of the aluminum veneer.

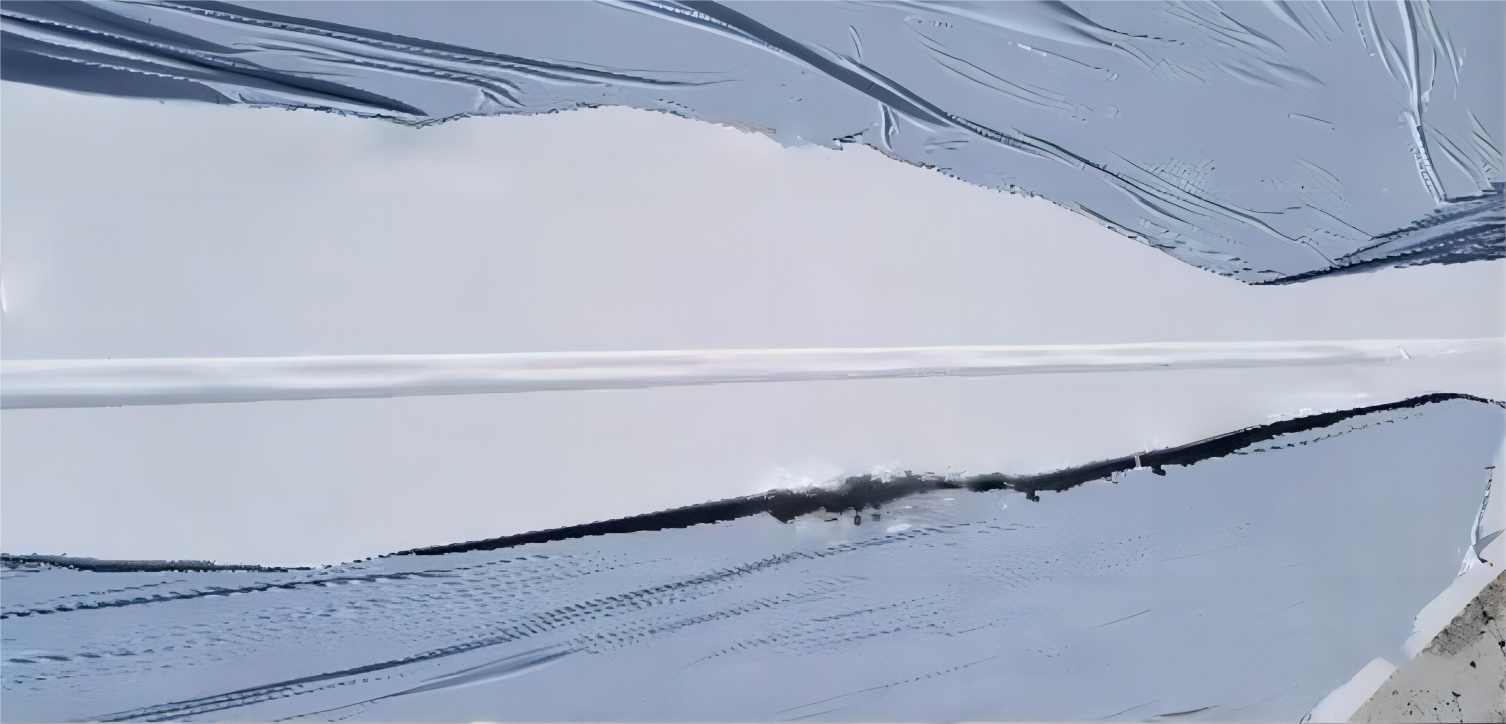

In the summer, there is often more rainfall, and aluminum veneers are typically installed using a cladding or dry hanging method, with certain gaps between the panels. If the joint treatment is improper or the sealing performance is not good, rainwater may penetrate into the joints, causing the aluminum sheet to become damp and expand, resulting in warping of the aluminum veneer.

The summer climate is humid, and the internal structure of the aluminum veneer usually consists of an aluminum sheet and an insulation layer. If the moisture resistance of the insulation layer is not good, moisture from the air may penetrate into the interior of the aluminum sheet, causing it to expand and resulting in warping of the aluminum veneer.

Construction Impact

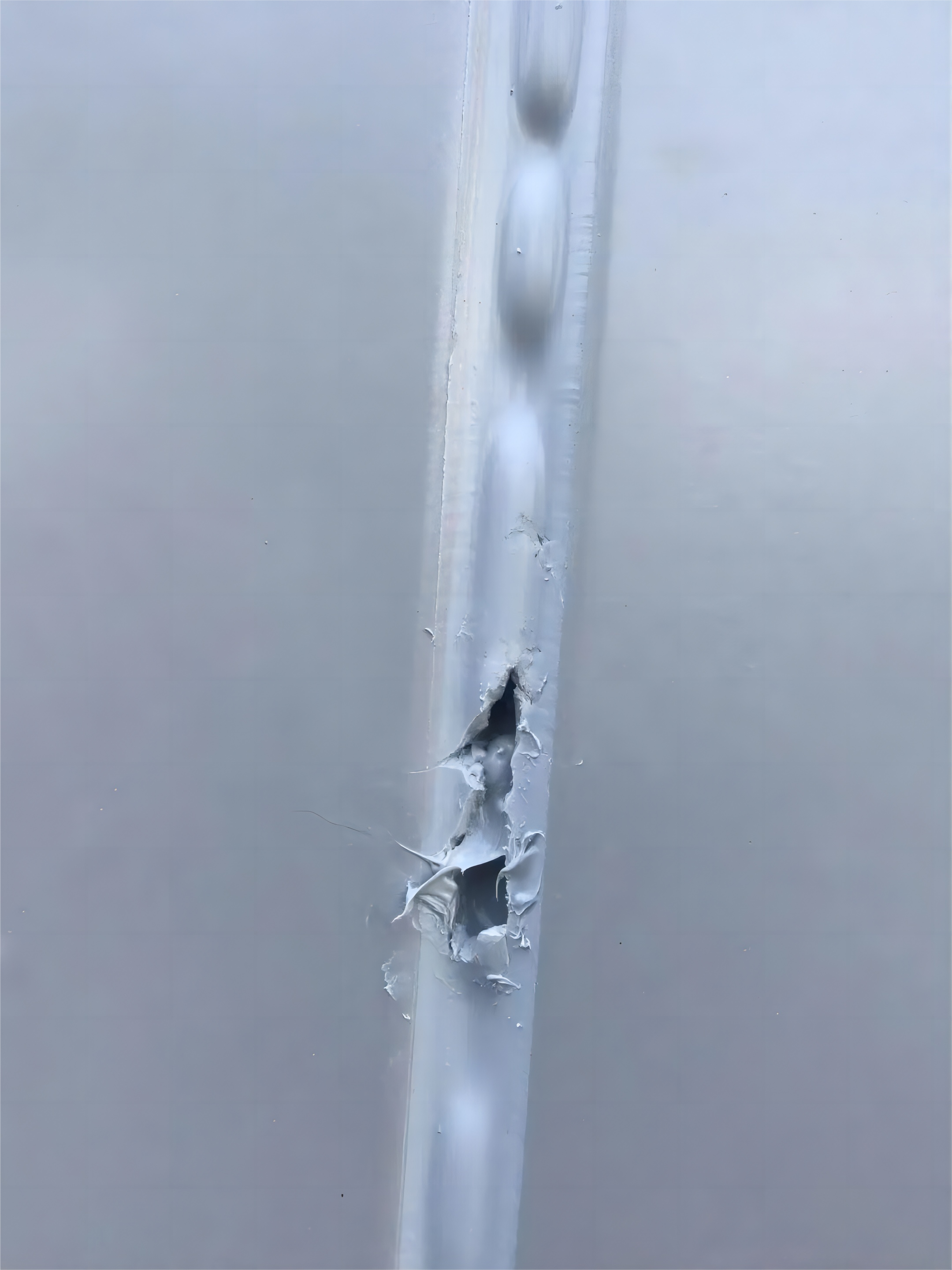

Due to the need to insert foam rods at the joint before construction to avoid three-sided bonding, the foam rods were not placed flat before gluing, and they were slightly raised. The rebound of the foam rods later can also cause the sealant to bubble up.

At the same time, low-density foam rods should not be used; only open-cell foam rods that comply with relevant specifications should be used. Before inserting the foam rods, it is essential to ensure that the joints are dry. Excessive humidity in the joints and substrate, the presence of rainwater, inadequate or uneven thickness of the sealant application can all lead to bubbling.

Additionally, when sealing different substrates, any movement before the adhesive is completely cured can also cause the sealant to bubble up.

Solution

①Pay attention to the construction environment

When selecting the construction weather, avoid choosing harsh weather conditions such as rain, strong winds, and intense sunlight. During the gluing process, ensure thorough cleaning and avoid any dust, water stains, oil stains, etc. It is best to use clean isopropanol or xylene for cleaning, or use a clean towel for wiping. Maintaining a dry and clean construction surface is crucial for its adhesion and curing.

②Pay attention to the construction time

1.Work promptly on cloudy days, as the small temperature difference between day and night reduces the deformation of the joint, making it less prone to bulging.

2.Choose a suitable time for caulking. Generally, the evening when the temperature decreases and the temperature changes are smaller is a more appropriate time for caulking.

3.Use appropriate shading measures, such as using dust-proof nets to cover the scaffold, so that the panels are not directly exposed to sunlight, reducing panel temperature, and minimizing joint deformation caused by temperature differences.

③Pay attention to the construction process

1.Before installing aluminum veneer, carefully inspect the panels and connections for any defects or damage to ensure they are in good condition.

2.During the installation of aluminum veneer, set reasonable expansion joints between the panels according to their thermal expansion properties to allow for sufficient space during thermal expansion and contraction.

3.Apply appropriate moisture-proof materials on the backside of the aluminum veneer to reduce the impact of humidity on the panels.

4.Regularly inspect and maintain the aluminum veneer, promptly repair and replace any damaged parts to maintain its good condition.

④Pay attention to material selection

1.Choose high-quality aluminum veneer materials to ensure excellent thermal expansion performance and stability.

2.Use reliable and weather-resistant adhesive for sealing. During on-site gluing, workers should follow the standard silicone weatherproof sealant application process to complete the gluing.

3.The diameter of the foam rod should be around 120% of the joint width, and qualified open-cell foam rods should be used. Keep the foam rods dry and ensure there is proper ventilation behind them to facilitate deep curing of the adhesive.

RELATED NEWS

- Not sure about the T4, T5, and T6 materials of aluminum profiles? This article h 2024-03-20

- How to use aluminum profile section design skills to solve extrusion production 2024-03-19

- Factors affecting the life of trimming and punching molds 2024-03-12

- Overview of Steel/Aluminum Welding Technology 2024-02-29

- Steel belt conveying direction 2023-09-26

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China