Industry news

Intelligent Manufacturing of Hot Stamping Formed Parts (Part 2)

The Necessity of Smart Manufacturing

Hot stamping forming is designed to achieve ultra-high-strength components and effectively address issues such as forming, springback, part dimensions, and accuracy. As previously mentioned, the process involves heating to the austenitic state, utilizing its good formability at high temperatures for hot stamping, and rapidly cooling to ensure the transformation from austenite to high-strength, tough martensite. This dual-purpose process consists of multiple stages and can only be accomplished through automation and smart manufacturing.

(1)For example, after heating the workpiece in the furnace, it needs to be quickly grabbed by a robotic arm and precisely placed into the forming die mounted on the press. The shorter the time required for this action, the better, as it ensures the temperature of the workpiece after entering the die and during stamping, facilitating the transformation into martensite. Therefore, only intelligent robotic arms can effectively perform this action.

(2)During the stamping process, it is crucial to minimize the exposure time of the workpiece to the air to maintain the forming temperature and reduce the formation of oxide scale. Therefore, the stamping machine also needs to be intelligent. The specific process requirements are stringent: the slide needs to drop as quickly as possible, but it must reduce the descent speed during workpiece forming to avoid too rapid forming and resulting defects. The final forming process must also ensure that the workpiece transforms into martensite during the cooling process to achieve ultra-high strength.

(3)After forming in the die, the cooling process of the die also needs to be intelligent. This involves considerations such as contact pressure, heat transfer coefficient, water flow rate, water volume, water temperature, holding pressure time, demolding temperature, and their relationships with the steel's phase transformation process. Additionally, it must account for structural defects introduced during the stamping process and their impact on the phase transformation process. This is clearly a simulation and intelligent process that integrates multiple disciplines such as solid mechanics simulation, phase transformation microstructure simulation, fluid dynamics, metallurgy, heat transfer, and structural mechanics.

(4)Considering the bus control in the production process, including sending the blank into the furnace, temperature parameters for heating, transportation, forming, and quenching of the workpiece after leaving the furnace, extraction of formed components, performance testing, feedback, process parameter adjustments, fault alarms, and troubleshooting, it is a complex intelligent operation process. Therefore, hot stamping forming components serve as an exemplary case of smart manufacturing.

The foundation for achieving smart manufacturing as described above lies in automation equipment and databases. Currently, China's hot stamping forming production lines have largely achieved automated production processes. However, realizing intelligent manufacturing processes still requires a significant amount of work, especially in terms of database construction, which remains a weak point in China's hot stamping forming field.

Intelligent Manufacturing of Various Typical Hot Stamping Components

Among the various types of components used in hot stamping processes, the most commonly employed technique is direct hot stamping. These components include various structural and safety parts in automobile bodies, such as front and rear bumpers, A-pillars, B-pillars, C-pillars, center channels, roof crossbeams, and inner door reinforcement bars. These components can be directly hot stamped using hot stamping steel, following the aforementioned smart manufacturing process, and relying on database construction or automated control systems to achieve the hot stamping process. This ensures uniformity, consistency of component performance, and process stability.

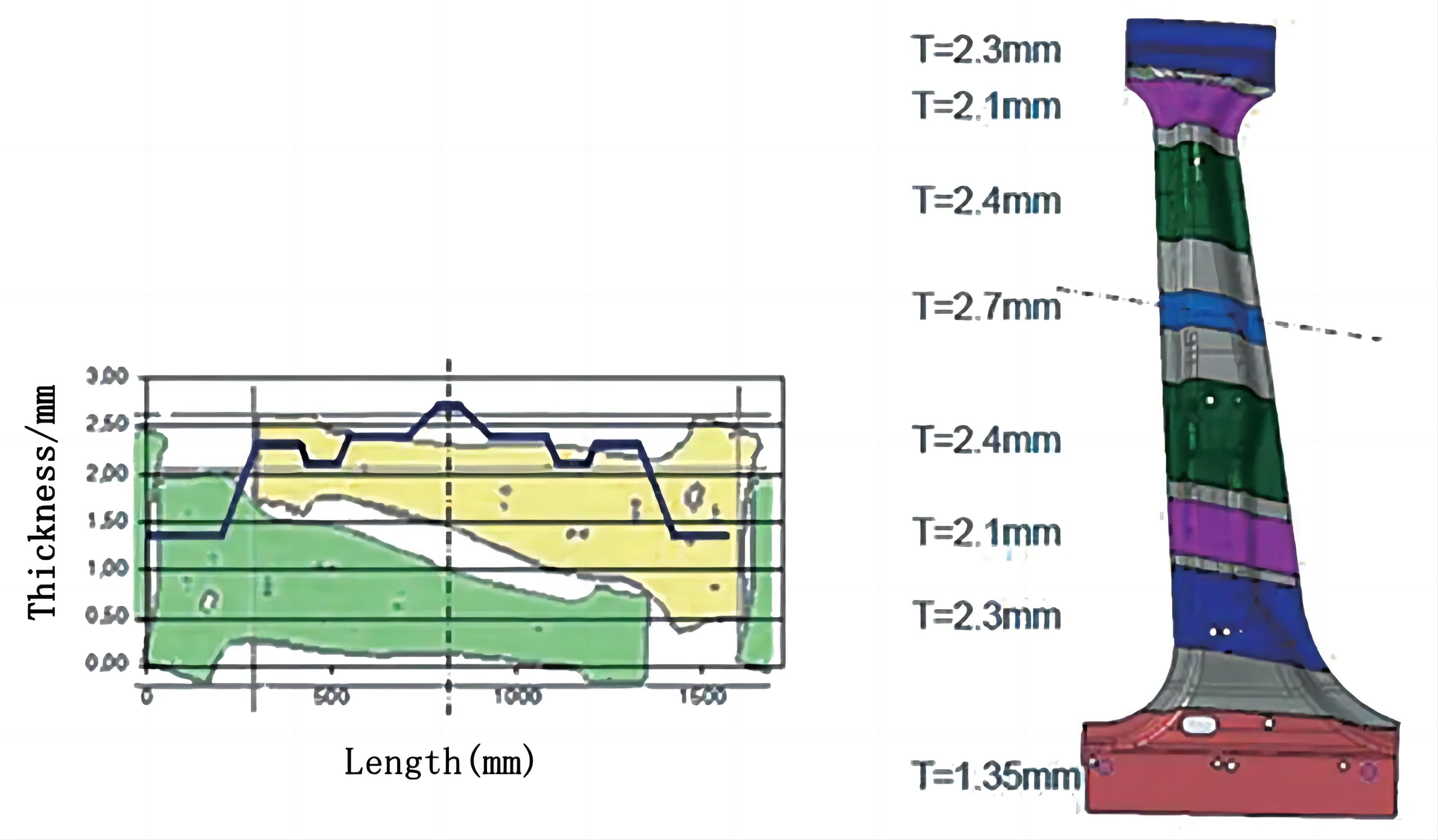

To meet safety performance requirements for different parts of the components, new structural designs have emerged for hot stamping components. Differential thickness plates, used in B-pillars, are one such example. The structural diagram of a differential thickness plate is shown in Figure 5. To implement the intelligent manufacturing process for such components, mold design or cooling channel design will be based on the raw material structure of the differential thickness plate and the structure of the designed component. This is done to ensure that components with different thicknesses can achieve the required hardness and strength levels. In addition to meeting the intelligent manufacturing process conditions used for direct hot stamping components, the intelligent manufacturing of these components must also meet the performance design requirements in mold design or cooling systems.

Figure 5 Thermoformed parts of B-pillars with different thicknesses

To enhance the crashworthiness of certain collision-resistant components, some vehicle models incorporate hot-stamped B-pillars with patch plates. These components involve connecting two hot-stamped blanks together using spot welding or other methods to create a single unit. They are then heated in an oven, followed by hot stamping in the die and cooling and quenching processes. This process reinforces the areas that require strengthening in the hot-stamped component, resulting in differentiated distribution of component performance. This approach reduces the use of molds, gauges, and fixtures, accelerates production cycles, and lowers production costs. For example, the Fiat 500 model utilizes patch plate technology in its B-pillars, further enhancing the safety of the B-pillar, reducing costs, and minimizing passenger injury in side collisions. The typical structure of such components is shown in Figure 6.

Figure 6 Thermoforming of patch plate

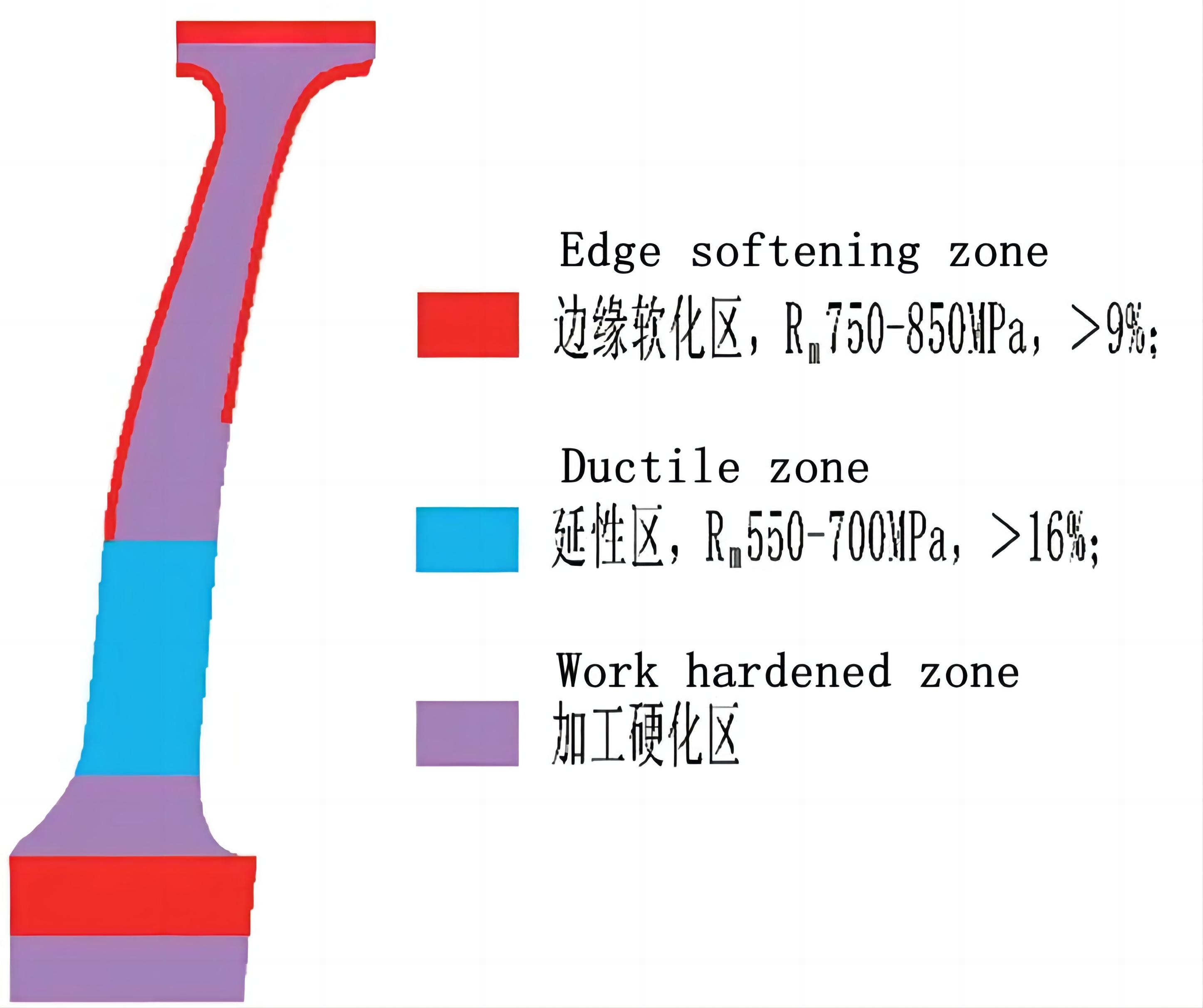

In automotive safety components like the B-pillar, different failure modes occur in various regions during collisions. As a result, different performance requirements are imposed on different parts of the component. Areas that need to withstand high impacts require high strength, while areas that need to absorb energy through deformation during impacts require appropriate strength and high ductility.

Therefore, a design concept known as strength-flexibility distribution is applied to these components to meet the varying hardness, strength, and ductility requirements in different areas when the component is subjected to impacts. This flexibility in performance distribution can be achieved through process design in hot stamping or the design of the cooling system in the die.

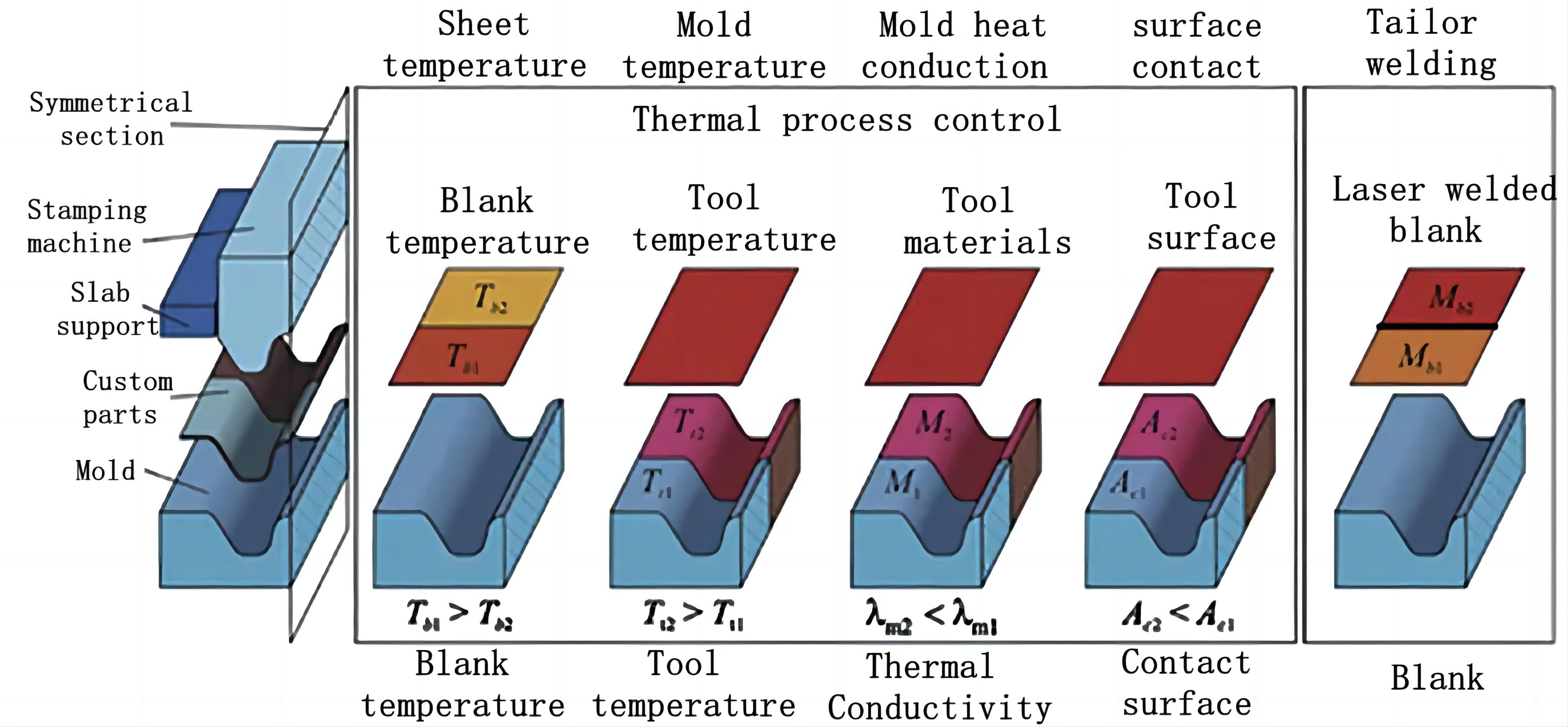

Using the B-pillar as an example, Figure 7 illustrates the different strength requirements for different areas. For components with significantly different localized strength distributions, technologies like hot stamping, as proposed by Schuler AG, can be employed. Additionally, local heating or cooling techniques for the mold can be used. These methods require knowledge of the transformation curves of different material regions and the relationship between the structure and performance of these regions. Clearly, this is a more complex intelligent manufacturing process. Different cooling techniques for various parts of the mold and heating methods and temperature control techniques for different parts of the sheet material, to meet varying strength performance requirements, can also be achieved through laser welding of plates with different cooling rates for different areas of the component, as shown in Figure 8.

Figure 7 Strength requirements for different parts of B-pillar

Figure 8 Mold and sheet metal laser tailor welding technology of different parts and intensity distribution of parts

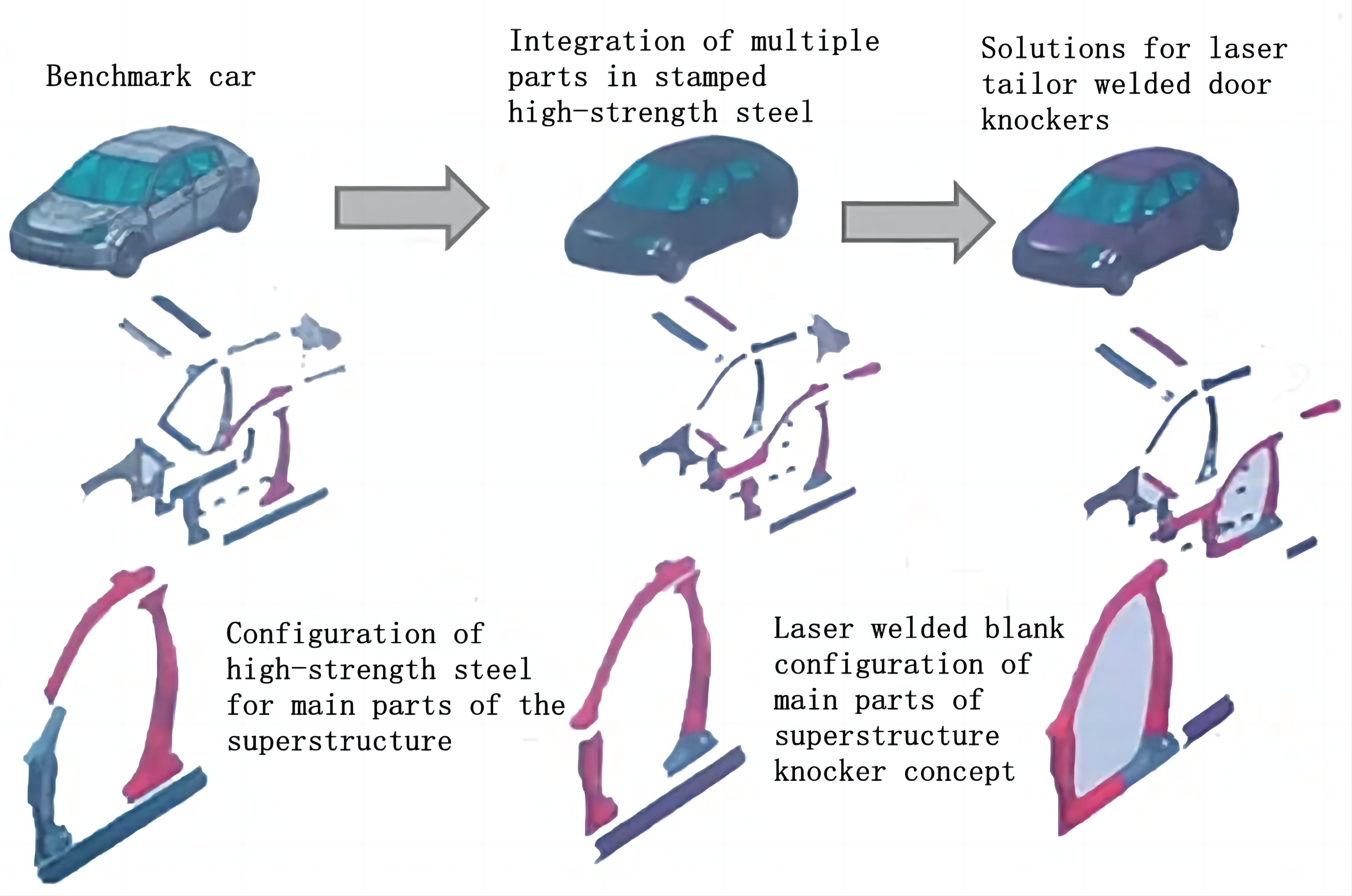

To reduce the cost of hot stamping components, minimize the manufacturing steps for parts, and decrease the number of weld points and welding processes in the vehicle structure, an approach involving optimized and integrated design is used to combine multiple parts into one, giving these parts component-like functionality. The earliest examples of such parts included welding together the A-pillar, B-pillar, door ring, and front bumper beam, effectively integrating four parts into one. Another example is the door ring technology introduced and implemented by ArcelorMittal. This technology involves hot stamping a pre-welded door ring into a complete unit in a single step, improving performance and reducing the welding quality requirements for high-strength components after hot forming. Depending on the strength requirements of different sections of the door ring, materials with varying hot forming properties can be welded together, thus meeting a broader range of safety performance requirements for these parts. This approach and intelligent manufacturing methods have now been extended to the integrated manufacturing of chassis components for new energy vehicles, as shown in Figure 9.

Figure 8 Mold and sheet metal laser tailor welding technology of different parts and intensity distribution of parts

Conclusion

After the year 2000, the Chinese automotive industry experienced rapid development in response to the demands for energy efficiency, emissions reduction, and safety. The application of high-strength and ultra-high-strength steel rapidly increased to meet the requirements of lightweighting, energy efficiency, emissions reduction, and enhanced safety in automobiles. Consequently, hot stamping emerged as an important and effective technology for producing ultra-high-strength and high-performance automotive safety components. In recent years, related industrial technologies have seen rapid development.

The hot stamping process represents a typical intelligent manufacturing process. Currently, China has achieved automation in the hot stamping process, and some steps have been automated. However, it has not yet reached the full level of intelligent manufacturing. To achieve true intelligent manufacturing, there is still a substantial amount of foundational work that needs to be done.

Achieving intelligent manufacturing of hot-stamped components requires a dual improvement in the automation level and reliability of production lines. It also entails the development of intelligent testing and databases for enhancing the performance and functionality of hot-stamped components. This includes refining database construction for the hot stamping process, perfecting the functionality testing and database development for various new structural components, and establishing automation equipment with independent intellectual property rights. Moreover, creating databases with self-learning capabilities is crucial for developing control processes and programs with independent intellectual property rights. These steps will further advance intelligent manufacturing in China's hot stamping industry.

RELATED NEWS

- Trump Raises Steel and Aluminum Tariffs to 25%: Impact on Global Trade and the A 2025-02-14

- Many countries have recently adjusted import tariffs, and foreign trade may rema 2024-03-26

- Photovoltaic frames and brackets are affected! The U.S. Department of Commerce r 2024-03-21

- Important benefits for the Australian market! Import tariffs on nearly 500 items 2024-03-14

- Ghana government proposes ban on bauxite exports 2024-02-29

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China