technological innovation

Why do designers choose aluminum panels?

A、Material Overview

Metal aluminum plate refers to a plate made of aluminum ingots through rolling processing, which belongs to a type of metal material and is commonly used in the construction industry.

B、Material Classification

From a logical classification perspective, aluminum plates used in the building decoration industry are mainly divided into two categories: "aluminum single panel" and "composite panel".

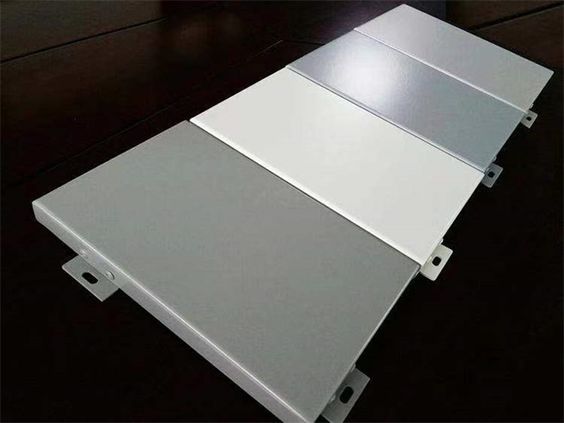

Aluminum veneer

Aluminum veneer

Aluminum veneer is a new building decoration material based on aluminum alloy sheet, after chromization and other treatments, and then formed by numerical control bending technology, fluorocarbon or powder spraying technology, because of its smooth surface , Good weather resistance, easy to clean, as wall and roof materials, widely used in indoor and outdoor environments of buildings.

Application of aluminum veneer in indoor space.

Application of aluminum veneer in building curtain wall

Popular science: Introduction of various aluminum veneers

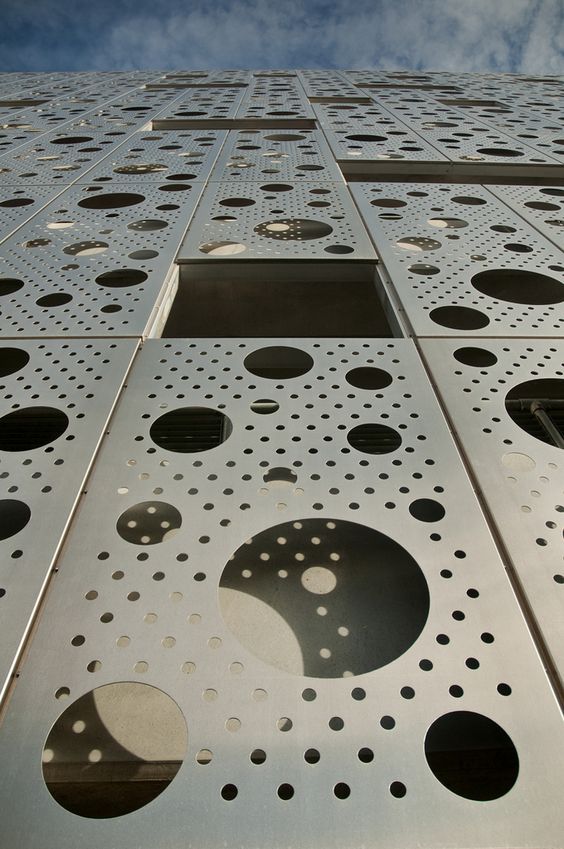

1. Punched aluminum veneer

Punched aluminum veneer is a decorative plate that drills holes of various shapes on the surface of the aluminum veneer by using advanced CNC punching equipment according to the design drawings, and various fillers can be added according to various special needs.

2. Carved aluminum veneer

Carved aluminum veneer is to use an engraving machine to carve various artistic patterns on the surface of the aluminum veneer. Through the combination of different patterns and different environments, it breaks through the traditional modeling concept, making the aluminum carved lines more lively and elegant.

![]()

![]()

3. Wood grain aluminum veneer

Wood-grain aluminum veneer is the effect that the surface of the aluminum veneer is treated with powder to form a wood strip texture. As a brand new green and environmentally friendly product, the pattern of wood grain aluminum veneer is luxury and luxurious, the color texture is lifelike, the pattern is firm and wear-resistant, and it doesn't contain formaldehyde and won't volatilize harmful and poisonous gas.

![]()

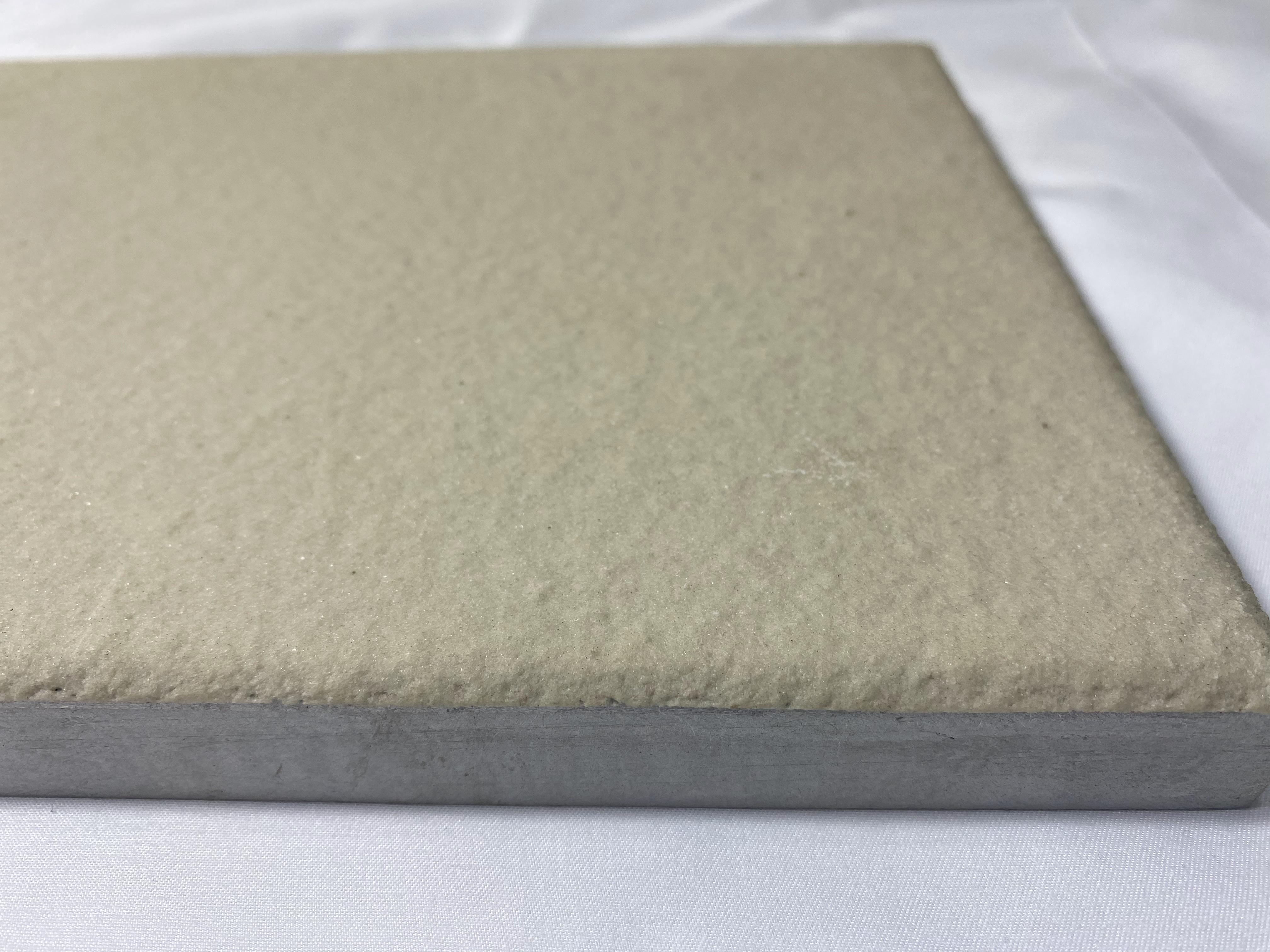

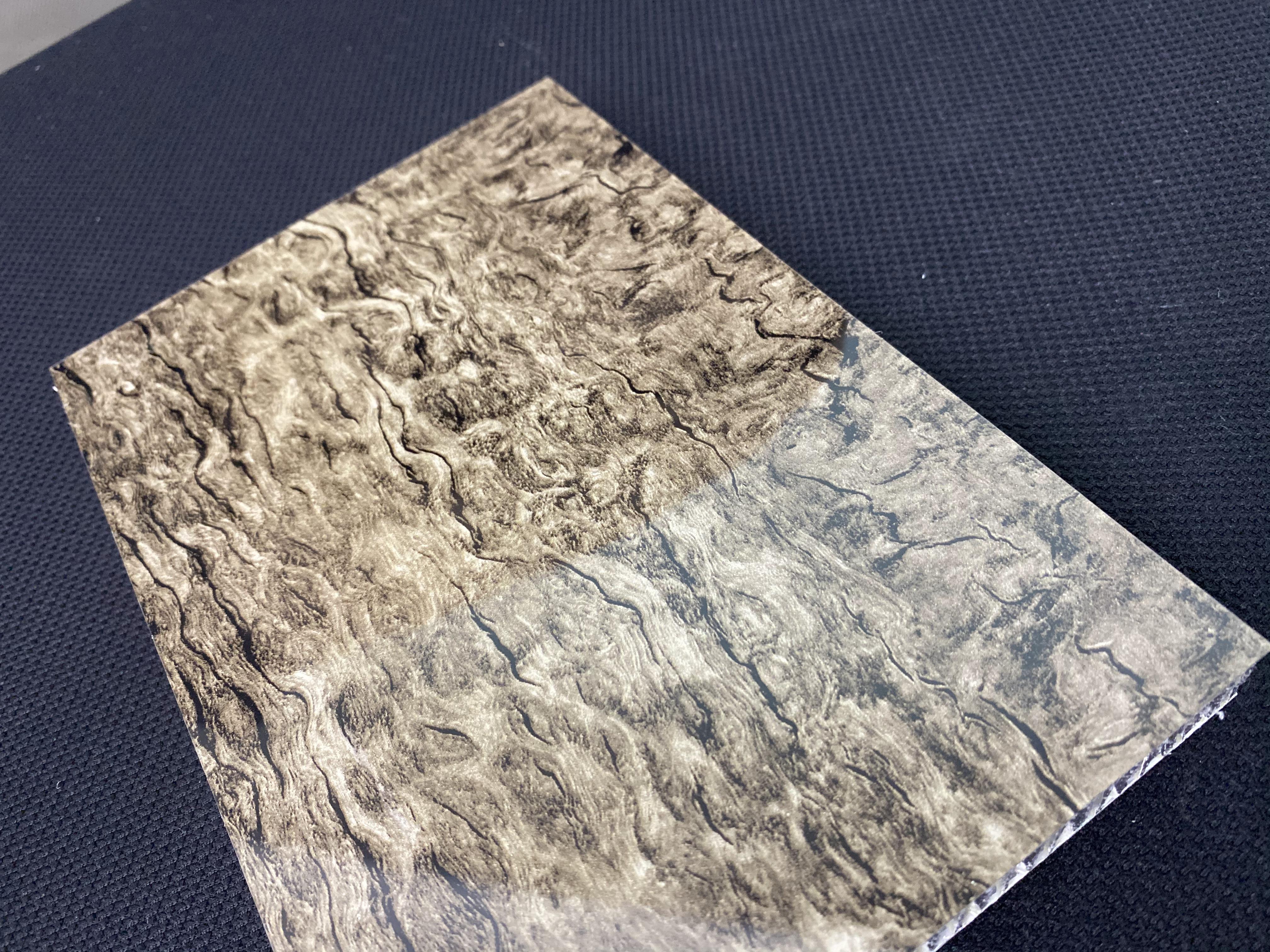

4. Imitation stone aluminum veneer

The imitation stone aluminum veneer is a new type of decorative material based on the aluminum veneer, which is processed by a special spraying process, so that the aluminum veneer has a strong stone three-dimensional effect.

![]()

![]()

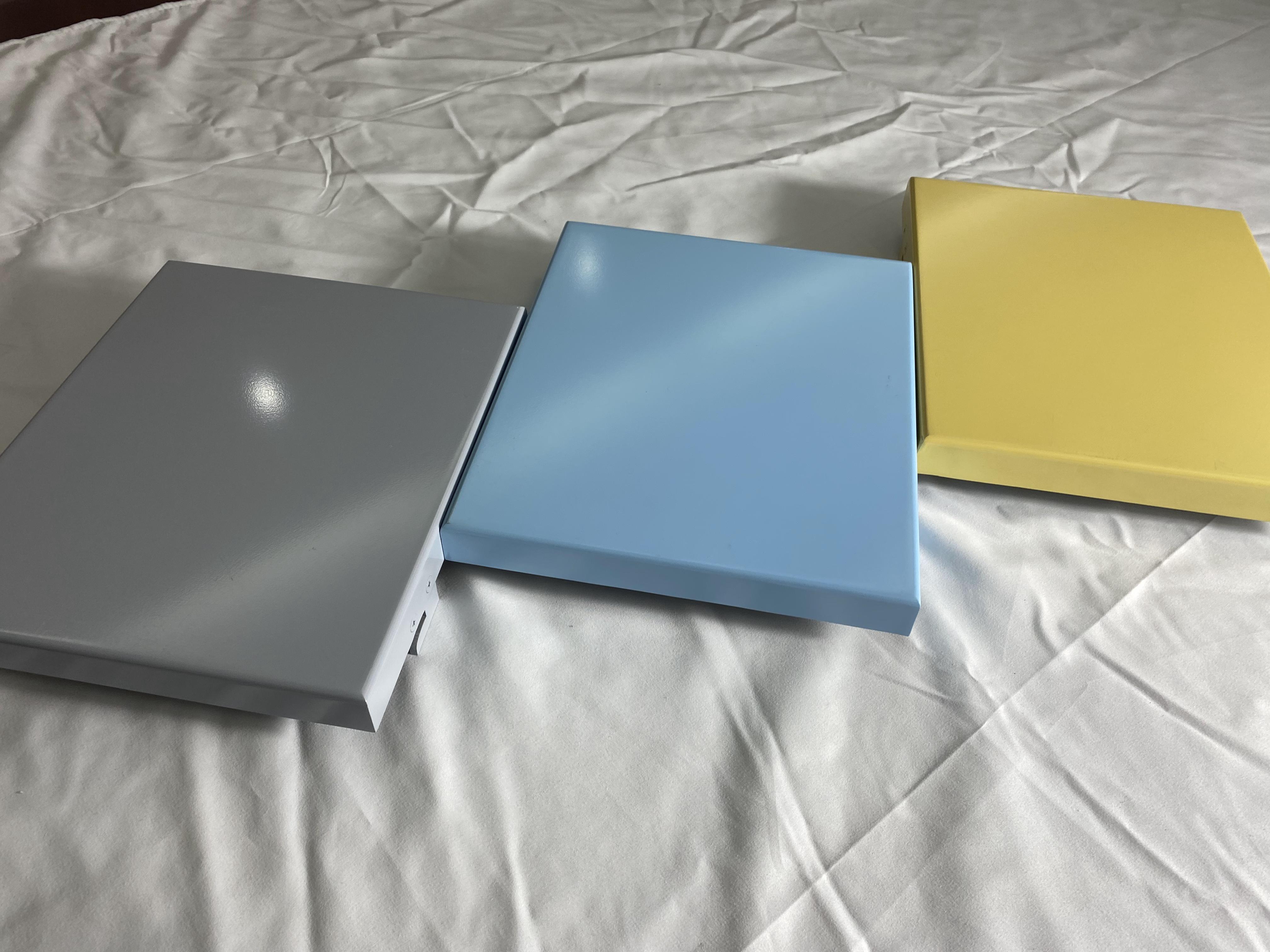

5. Fluorocarbon aluminum veneer

Fluorocarbon aluminum veneer is also called flat aluminum veneer. The surface coating of fluorocarbon aluminum veneer is divided into fluorocarbon spraying, powder spraying, polyester paint spraying and fluorocarbon pre-roller coating according to customer needs. Fluorocarbon spray surface coating is divided into two coatings and one baking, three coatings and one baking and three coatings and two baking according to the processing technology, and the powder spraying surface coating is one coating and one baking. The color of fluorocarbon aluminum veneer can be freely chosen by customers.

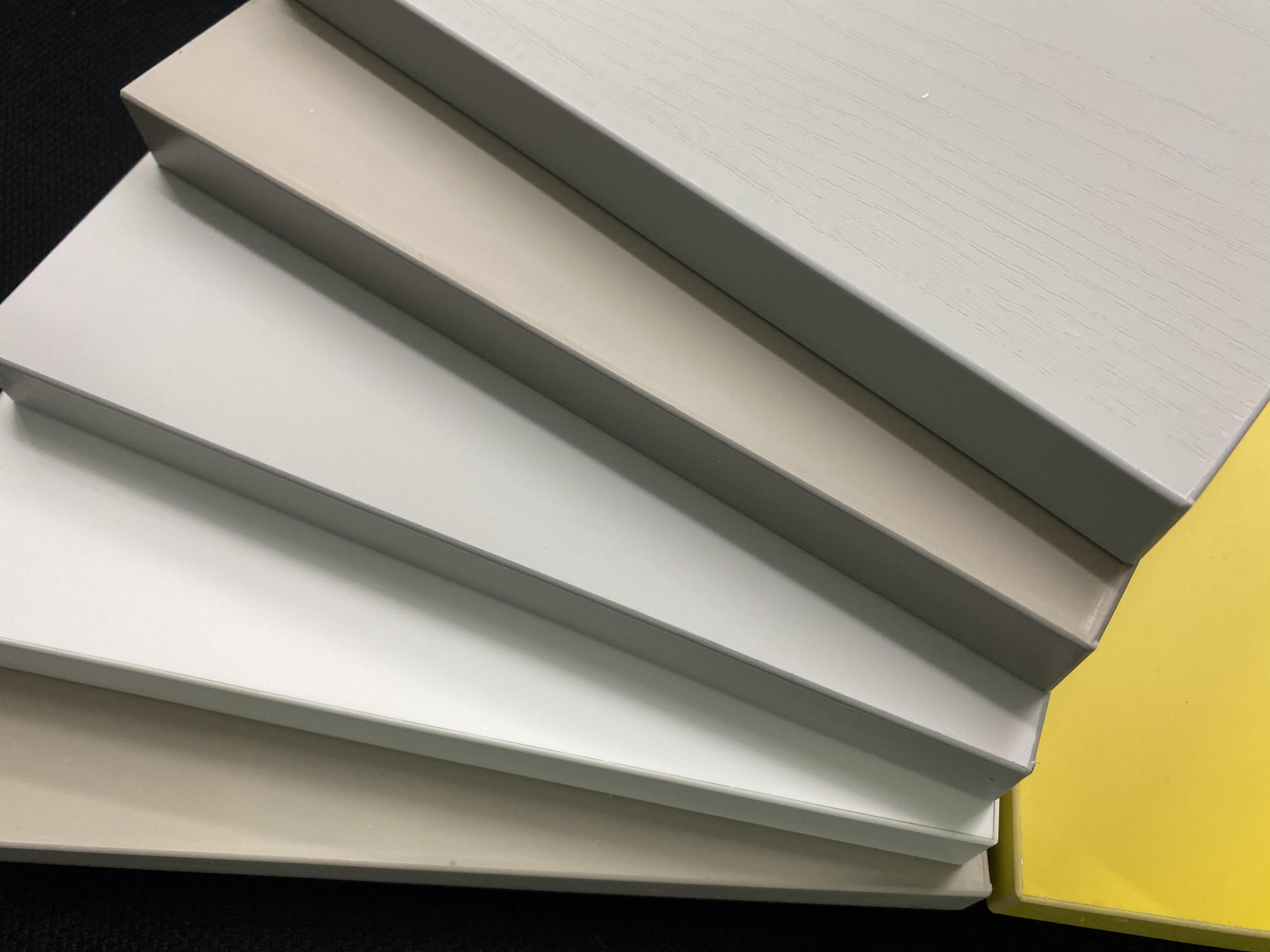

6. Shaped aluminum veneer

Shaped aluminum veneer means that according to different designs, the aluminum veneer can be made into curved roll aluminum veneer, tapered aluminum veneer, curved aluminum veneer and other shapes. Shaped aluminum veneer is an aluminum product with strong decoration and aesthetics.

C. Composite board

Aluminum composite panel

Aluminum composite panel is a general term, which mainly refers to the use of chemically treated coated aluminum panels (aluminum veneers) as surface materials through various complex processing methods, which are compounded on suitable base materials to form aluminum composite panels. According to the different composite substrate materials, aluminum composite panels have different material properties.

For example, the common aluminum-plastic panel is a composite panel of plastic + aluminum veneer, which not only retains the characteristics of plastic materials, but also overcomes the shortcomings of plastic materials through metal materials.

Application of aluminum-plastic panels in building curtain walls

Application of aluminum-plastic panels in the interior

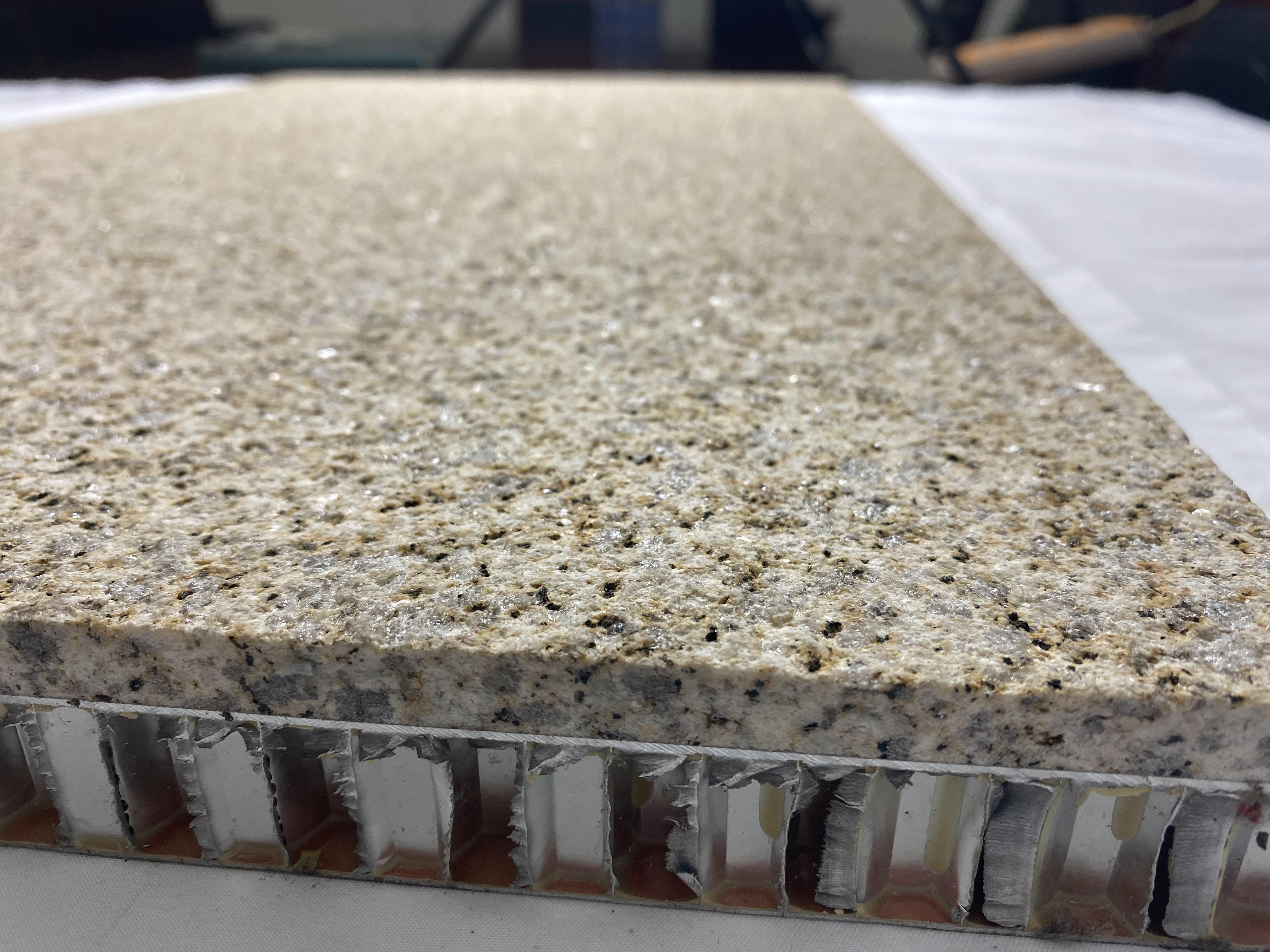

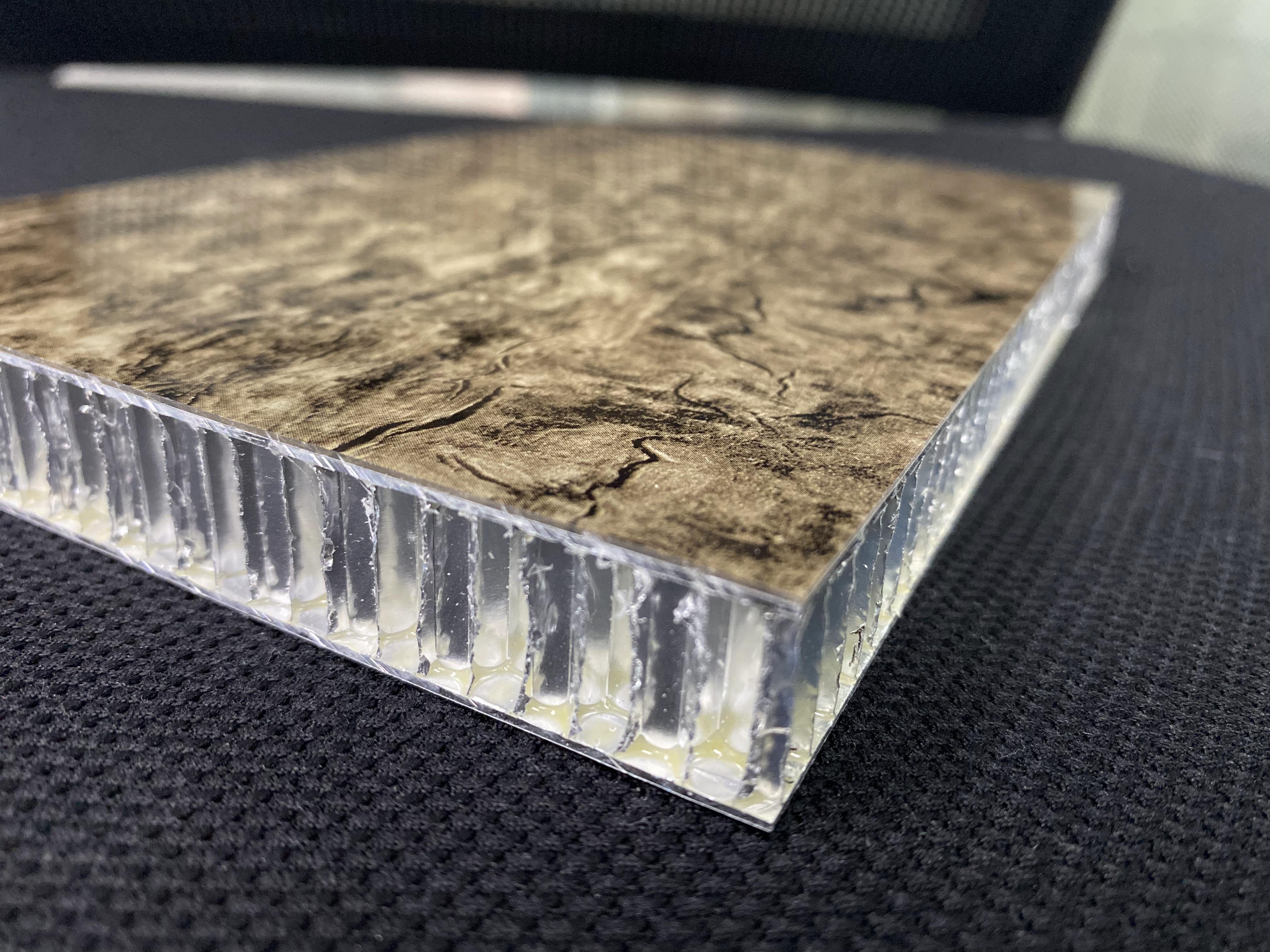

Another common aluminum composite panel is honeycomb aluminum panel: it is a composite material composed of honeycomb metal + aluminum veneer. In addition to retaining the decorative performance characteristics of the aluminum veneer, the base layer of the honeycomb metal structure greatly compensates for the shortcomings of the aluminum veneer that is easy to bend. In more and more large-scale space occasions, in order to ensure the flatness of the decorative material , will use this material.

Metal honeycomb panel

![]()

03. Material properties

Advantages of aluminum veneer a. Light weight and high strength. The 3.0mm thick aluminum plate weighs 8kg per square plate and has a tensile strength of 100~280N/m. (N=Newton, mechanical unit)

b. Good durability and corrosion resistance Use PVDF fluorocarbon paint or powder spraying to ensure excellent weather resistance and corrosion resistance.

c. Easy to process The aluminum plate can be processed into various geometric shapes such as plane, arc and sphere to meet the complex modeling requirements of buildings.

d. Uniform anti-coating and various colors. The advanced electrostatic spraying technology makes the adhesion between the paint and the aluminum plate uniform and consistent, with various colors and large selection space, which meets the requirements of architecture.

e. It is not easy to be stained and easy to clean and maintain. The non-adhesive property of the fluorine coating film makes it difficult to attach pollutants to the surface and has good self-cleaning properties.

f. Installation and construction are convenient and fast. After the aluminum plate is processed in the factory according to the order drawing, it is directly installed on site, without on-site cutting and processing. Therefore, the construction efficiency is very high, especially when faced with some polygonal and two-dimensional surface modeling, this feature is even more reflected.

g. It can be recycled and reused, which is beneficial to environmental protection. Aluminum panels are different from decorative materials such as glass, stone, ceramics, and aluminum-plastic panels. They can be 100% recycled, and the residual value of recycling is high.

Disadvantages of aluminum veneer

① The biggest disadvantage of aluminum veneer is that it is difficult to achieve a highly restored effect in replacing the touch of traditional materials.

② When aluminum veneer is used as decorative material in a large area, it is difficult to ensure the flatness of the aluminum plate, and it is very easy to corrugate. Therefore, in the case that the flatness of the aluminum plate is required, it is not recommended to use an aluminum veneer, but a honeycomb aluminum plate is better.

If the metal plate is too thin, there must be unevenness on the surface

Of course, the flaws do not conceal the advantages. It is precisely because of these characteristics that these aluminum veneers have such a high status in the metal sheet industry, and are widely used in the indoor and outdoor environments of buildings.

04. Material technology

1. Spraying treatment The surface layer is sprayed with fluorocarbon coating, the process is simple, but there will be the disadvantage of uneven distribution of color thickness.

2. Roller coating treatment After degreasing and chemical treatment, roll coating; the surface smoothness of this process is higher than that of spraying process. And it can realize wood grain, bamboo grain, imitation stone and other effects.

3. Anodizing treatment

Using electrolysis to form a protective film on the surface, the natural soft metal texture of aluminum is fully preserved. Make the aluminum plate have higher hardness, wear resistance, adhesion performance, corrosion resistance, electrical insulation, thermal insulation, and oxidation resistance. The surface is not charged and does not attract dust. Strong self-cleaning ability, resistance to cleaning, and anti-fingerprints. However, due to the high level requirements for the base material (5 series aluminum), the price is relatively high.

4.High-gloss film or phantom film for lamination treatment, compounded by professional adhesives. The luster is bright, and there are many varieties of designs and colors to choose from. It is waterproof and fireproof, has excellent durability and anti-fouling ability, and has excellent anti-ultraviolet performance.

5. The metal wire drawing treatment is made of aluminum plate as the base material, and the surface of the imported diamond cloth wheel is drawn, and it is formed by various chemical treatments such as pressing and rolling. The appearance color is bright, even and fashionable, giving people a strong visual impact.

6. Punching treatment Aluminum veneer is suitable for perforation treatment, and is also widely used in building indoor ceilings. Combined with appropriate perforation surface treatment, it can be used as a good sound-absorbing material.

Creative punching aluminum plate

05. Purchase of aluminum veneer

1. View its shape The size of the aluminum veneer should be standardized and neat, with uniform thickness, smooth surface and straight board shape. The selection of high-quality aluminum veneer is strict in the selection of aluminum raw materials, with few impurities, and the aluminum veneer will not be deformed after high temperature during spraying, and the processing equipment and management of sheet metal processing will affect the flatness of the aluminum veneer.

2. Smell the smell and peel off the aluminum plate, there should be no pungent organic solvent smell.

3. Look at the thickness The high-quality aluminum veneer has uniform wall thickness, and the aluminum veneer is tightly combined. The quality and thickness of the aluminum veneer can meet the national standard. According to the national standard, the thickness of the exterior wall panel should be 4mm, and the thickness of the interior wall panel should be 3mm. The aluminum plate of the exterior wall panel is obviously harder than the aluminum plate of the interior wall panel.

4. Look at the spraying process. High-quality aluminum veneer should use the top aluminum veneer spraying line. During the spraying process, there will be no penetration of metal and non-metallic debris. The process precision is high, and the surface and inner layers feel smooth and smooth. No mottling.

5. Peeling test The aluminum veneer and the core layer should not be easily peeled off. After peeling off, there should be a layer of napped film on the aluminum plate and the plastic core material.

6. The surface treatment of aluminum veneer in use occasions includes powder spraying, fluorocarbon spraying, etc. According to the use environment, powder spraying can generally be used for indoor use, and outdoor use must withstand various harsh natural environments and sunlight. Only by spraying with fluorocarbon can the aluminum veneer not change color or oxidize for a long time.

7. Aluminum veneer brand There are many aluminum veneer manufacturers in the market. The editor recommends choosing a good aluminum veneer manufacturer. Because a better aluminum veneer manufacturer not only guarantees product quality, but also designs a set of reasonable solutions for customers to choose according to customer needs, and also provides thoughtful after-sales service.

06. Aluminum veneer cleaning and maintenance

1. Aluminum veneer cleaning The cleaning of aluminum veneer and glass on the exterior wall requires outdoor and high-altitude operations. Professionals must be sought and vehicles such as hanging baskets, hanging plates, and lifting platforms must be used. Cleaning method: first wash the surface of the aluminum plate with a large amount of water, use a soft cloth soaked in water-diluted detergent to gently wipe the surface of the test plate, and then rinse the surface of the plate with a large amount of water to wash away the dirt. Then check the surface of the board, use detergent to clean the places that have not been cleaned, and then rinse the board surface with clean water until all the detergent is washed away.

2. Aluminum veneer maintenance The maintenance of aluminum veneer curtain wall is mainly to check the sealing condition between the panels. The sealing between the boards is mainly based on the sealing rubber strip and glass glue. If it falls off, it must be repaired and replaced in time. When repairing and replacing, do not step on the aluminum, and do not pull on the frame for support. This is easy to wear the aluminum veneer curtain wall or prone to accidents. Always check the junction between the frame and the wall. If the screws at the junction are found to be loose, they should be tightened immediately. If the screw footing is loose, apply a small amount of cement to seal it with epoxy super glue.

Disclaimer: The content of this article comes from the Material Aesthetics Museum +, etc., and is edited by aluminum processing. The purpose of citing is to convey more information, and it does not mean that this official account agrees with its views and is responsible for its authenticity. If it involves work content, copyright and other issues, please call or write to us, we will deal with it in time!

RELATED NEWS

- Not sure about the T4, T5, and T6 materials of aluminum profiles? This article h 2024-03-20

- How to use aluminum profile section design skills to solve extrusion production 2024-03-19

- Factors affecting the life of trimming and punching molds 2024-03-12

- Overview of Steel/Aluminum Welding Technology 2024-02-29

- Steel belt conveying direction 2023-09-26

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China