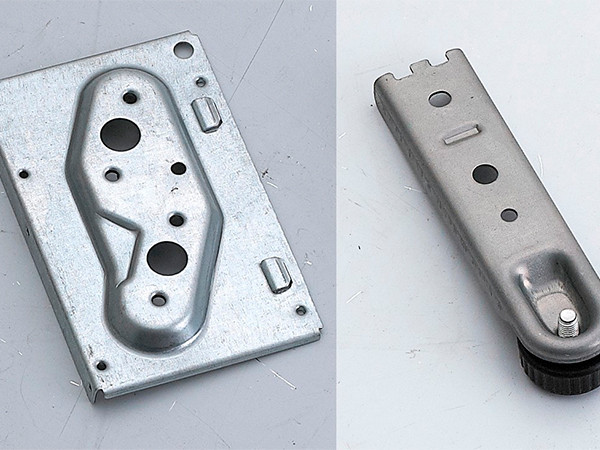

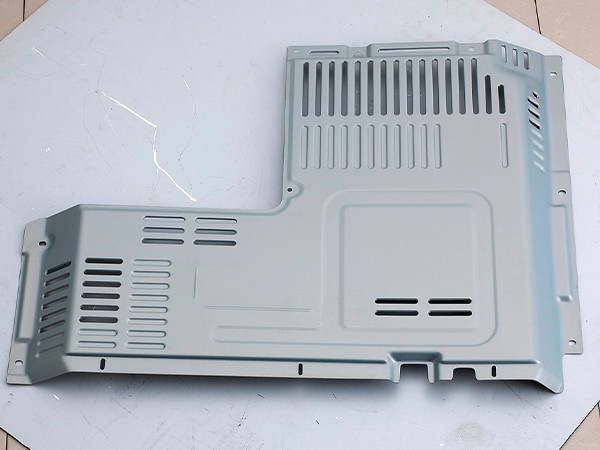

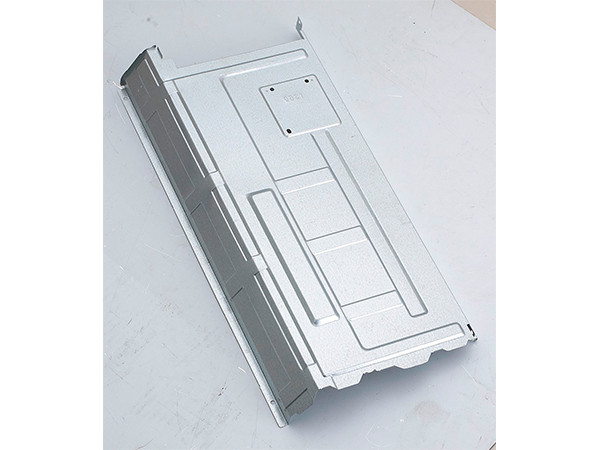

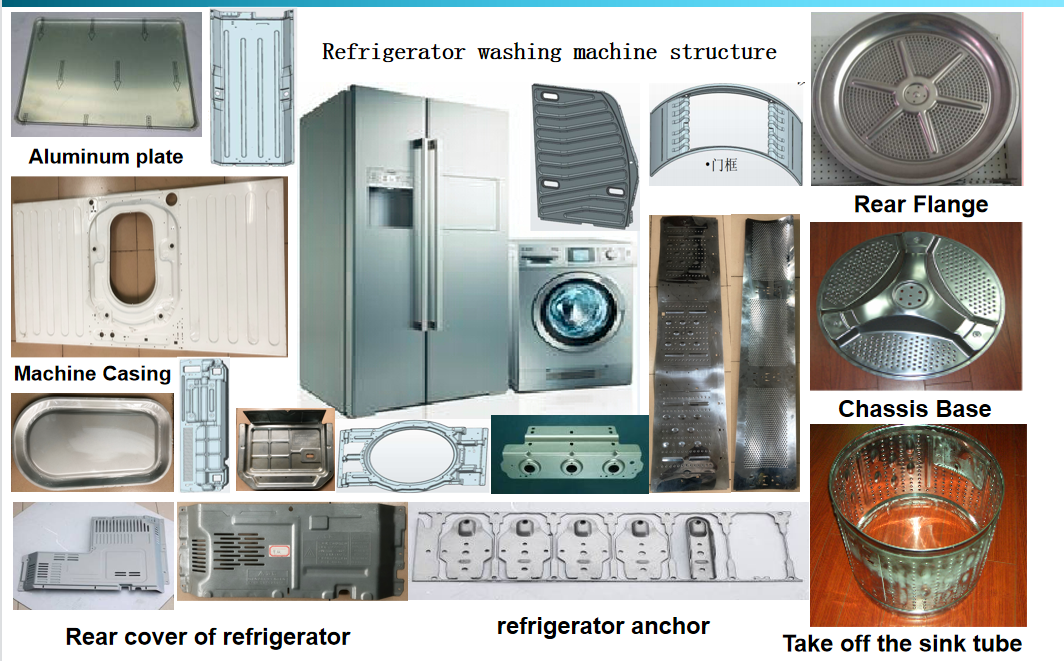

Refrigerator aluminum stamping parts high temperature and low temperature resistance, corrosion resistance, not easy to deformation, good performance

Refrigerator aluminum stamping parts high temperature and low temperature resistance, corrosion resistance, not easy to deformation, good performance

GDAA production base is located in Lishui Town, Nanhai District, Foshan City. GDAA has the ability to design and manufacture automobile steel plate molds. Business scope includes: automotive sheet metal mold design, manufacturing, parts stamping, welding, polishing, surface treatment; Automobile exhaust pipe tail cover manufacturing.

GDAA has an experienced management team, including many mold designers with more than 20 years of experience; The company implements IATF16949 quality management system. The person in charge of manufacturing and quality has rich experience in auto parts industry management. Mold manufacturing, stamping production equipment is perfect, and has been pushing forward the stamping, welding, polishing and other process automation transformation.

Since 2019 the company started the manufacturing of automobile exhaust pipe end cover, depends on customer support and their own efforts, now has the production capacity of annual output of 700000 sets of exhaust pipe end cover, can realize the whole process from product design in our factory, mould manufacturing, stamping forming, welding, polishing, cleaning, sorting, packaging, such as one-stop service delivery.

Specification | Aluminum stamping parts |

Grade and Temper | 6063 6061 6060 T5 (T6) 7000 series,2000 series, 3000 series, 5000 series, |

Thickness | 1.0--20m |

Cross-section | 8--650mm |

Surface Treatment | Hardcoat Anodizing,Powder Coating,Wood Grain,Electrophoreses, |

Advantages | 1. Good quality in material; 2. Strick quality control system 3. One-stop Customized after-sales service |

Production capacity | Aluminium extrusion,cutting ,milling,drilling,precision CNC machining,forging and Stamping,aluminium die casting,aluminium welding |

Standard | GB/T 5237,EN755-9,EN12020,DIN,JIS,ASTM |

Certificate | 1) ISO9001-2008/ISO 9001:2008; 2) CQM Certification; 3) SGS, CE, BV, JIS, AS, available |

Guarantee | Surface color guarrantee for 10~25years is available indoor and outdoor(seaside). |

Settlement Terms | Charge by final actual weight or by drawing theoretical weight |

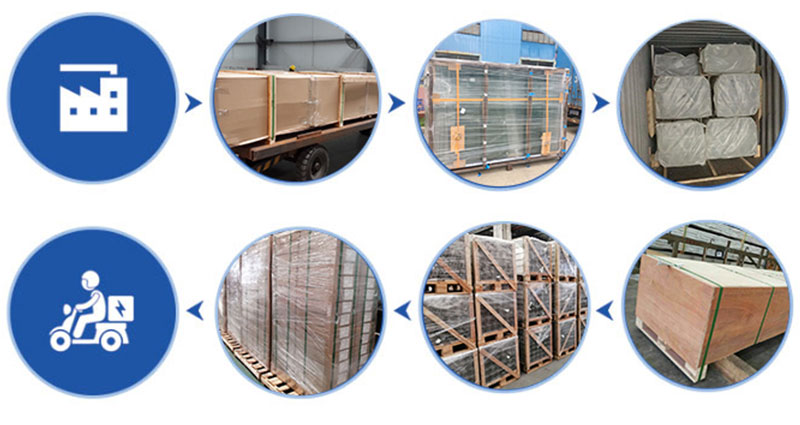

Our factory view

R&D team

We have technical cooperations with 116 members of Dali Aluminium accociation and scientific research

cooperation units. we realize the effective integration of orders and resources, the full use of equipment,

and the complementary advantages of technology in order to offer variou customized solutions.26 techinical

experts insure we can offer professional pre-sales services.

ODM&OEM service

The main production equipment:

1. 5 CNC machining centers

2. four column double action hydraulic press (275T~500T) 3 sets

3. 7 large and medium-sized punching machines (200T~600T)

4. small punching machine (110T~160T) 11 sets

5.100KW resistance welding machine 10

6. ultrasonic automatic cleaning line 1

7. fiber laser welding machine 1

8. 13 sets of environmental protection polishing equipment

9. 1 automatic ring assembly line

It can meet the annual production capacity of about 700,000 sets (60,000 sets/month) of exhaust pipe tail covers.

In addition, it is planned to introduce 4 sets of spot welding manipulator workstations, 1 (5 manipulator) automatic stamping production line.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China