News

How to drill perfect holes on aluminium sheet?

We are in the drilling process with thin plate, at the entrance and exit of the hole will appear not round, into polygonal, hole mouth flying edge, burr is very large, and even thin plate twisted deformation, hole is torn, especially in the processing of copper, brass, aluminum (aluminum alloy in fact, the harder the better the processing) the toughness of these materials thin plate (thickness of 0.1 ~ 1.5mm) when.

Causes

Aluminum alloy hardness is not high, many times processing shallow holes many people's choice is the ordinary twist drill, this situation may be the product's hole size requirements are not very strict.

On the one hand, when the drill is about to drill through the thin plate, the processed material will appear plastic deformation, which should be cut by the drill near the outer edge of the part of the edge of the triangular part of the axial cutting force by the deformation of the deformation to the outer side of the bending, and in the outer edge of the drill chamfering and the edge of the edge of the belt prismatic surface of the role of further curling, the formation of curled or burr edges.

On the other hand, when drilling through the thin plate, the ordinary twist drill bit is prone to suddenly lose centering ability, the workpiece is prone to jitter, and the axial force drops sharply, the workpiece material rebounds rapidly, the feed and cutting load become large instantly, which may lead to knife, broken drill bit or even tearing the workpiece.

Solution

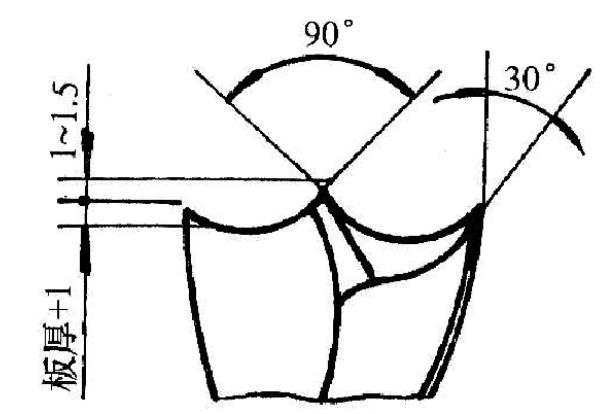

For drilling holes in thin aluminum plates, do not use ordinary twist drills, but use thin plate drills (the crescent arc of the basic group drill is increased until there are only three sharp points), as shown in the above figure .

Thin plate drill when drilling the drill tip first cut into the workpiece, so that the drill core has not yet drilled through the outer tip of the knife has been cut in the workpiece circular groove, play a good role in centering, can quickly cut away from the middle of the material, to get the required hole. Use this thin plate drill to drill aluminum thin plate cleanly, safely and reliably.

1、Other points to note

2、Sharpen the drill center as much as possible.

3、When the diameter of the drill is large, it can be connected with a segmented arc, but it is necessary to ensure the size of the edge tip angle and the depth of the arc.

4、The back angle of the arc is appropriately reduced, which can enhance the centering effect of the drill core part and avoid vibration.

In case of drilling thicker plates, the outer edge tip should be slightly chamfered and ground into a short flat edge to enhance the strength of the outer edge tip and improve heat dissipation.

5、When drilling brass, reduce the leading angle at the tip of the outer edge to zero.

6、This drill can also be used for drilling holes in wood and thin plywood.

RELATED NEWS

- O+ Tower Project Showcases Our Production Prowess 2025-02-20

- Guangdong Aluminum Association and Moscow University Business School visited Gua 2024-12-12

- Guangdong Aluminium Association International Trade Co., Ltd. signed an overseas 2024-11-21

- Guangdong Aluminum Association International Trade Co., Ltd. Participates in the 2024-11-15

- Simplified Approach to Spandrel Area Treatment in Curtain Wall Glazing 2024-10-25

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Manager:Miss Jasmien

Phone: +8618825429836

E-mail: info@gdaa-cn.com

Whatsapp:+8618825429836

Add: Headquarter:No.8,Yixian Road,GDAA Mansion,Guangfo Zhicheng, Dali Town,Foshan,Guangdong.China